.jpg)

☞ Extrusion technology is mainly used for producing floating feed for tilapia, which accounts for around 40–50% of total tilapia feed production and retails for 7–10 BDT/kg (USD0.09–0.128/kg) more than sinking feed. The production rate of grower feed is 1–2 tonnes/hour greater than that of starter feed, while energy consumption in machine operation and protein inclusion costs are higher for starter feed than for grower.

.jpg)

These two processing lines in the new factory feature: One is a five-to-six tonnes per hour (tph) extrusion line specialised in the production of high-quality micro floating fish feed of 0.6-4.0mm, using a SJPS120x2 Extruder, a SKGD2000-8 Dryer and a PTCL2000 Vertical Coater as key machines. The other is a 10-12tph pelleting line that presses a

Fish Feeds and Production Machine in Bangladesh – Fish . No matter which type of feed machine you decide to buy, the four tips should be taken into consideration. Get Fish Feed Extruder Price Now! 1. Quality Quality is key, the heart of fish feed production. You should know the structure, materials that made of machine, fish feed quality and

Nov 23, 2016 · The effect of sinking or floating fish feed depends obviously on several factors prior the extrusion and in the extrusion process by itself. The ability of the feed to sink or float will depend on what kind of die insert land lengths you will use and also the degree on the expansion at the die plate of the extruder.

.jpg)

Jul 10, 2021 · Fish Feed Processing and Production. July 2021. In book: The Blue Bonanza: A Manual for on the job Training Programme for VHSE students on Advances in Fisheries & Aquaculture Techniques (pp.99-103

.jpg)

1.Determine the scale of animal feed mill. 2.Determine the feed process and recommend animal feed machine. 3.Control mode selection. 4.animal feed manufacturing plant structure selection. 5.Planning the general drawing of animal feed mill plant site. 6.We devote ourselves to undertaking all animal feed production line 1-100 T/H.

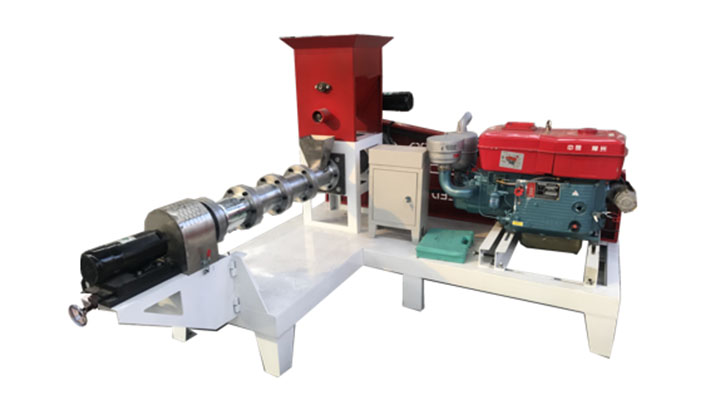

According to the moisture content of raw materials treatment, fish feed extrusion process can be divided into two types – dry type extrusion and wet type extrusion. Dry type extrusion process: in the process of extruding, it adopts the heat from friction for warming materials, forces materials to pass through die hole and gets certain pressure simultaneously under the action of screw extrusion.

9.To improve fish feed quality, extrusion process can be used to develop extra feed materials, such as full-fat soybean powder, feather powder, blood powder, etc. 10.It is easy to inspect and control fish feeding condition to keep an optimal fish production.

.jpg)

In many food and fish feed companies, engineer often has an opportunity to use different extruders to process a product. These extruders can be single- or twin-screw extruders, or different capacities. In general, the extruder selection is an art work and based on experience in extruder mechanical characteristics. Thermo Extrusion Tech provides

Apr 01, 2004 · Depending on the processing conditions and ingredients used, different products such as floating or sinking extruded feed can be produced. Extrusion process Extrusion cooking involves the application of mechanical energy supplied by the shearing and mixing action of the extruder screws. Photo courtesy of Clextral.

.jpg)

3、xtrusion, including dry extrusion and wet extrusion, is the aqua fish feed extrusion process where the raw material is pushed forward. 4、Dry extruders are usually single-screw extruders with screw segments and steamlocks (choke plates) on the shaft to increase shear and produce heat.

2. Fish Feed Production Line The process of making your own fish feed pellets generally includes grinding, mixing, extrusion, drying and packing. a.Grinding by fish feed grinder: increase the contact area between feed, improve the digestive absorption of substance, nitrogen and energy and reduce the feed coefficient. Generally, the materials for fish feed pellets should all pass through the 40 mesh sieve and not more than 20% left on the 60 mesh sieve.

Oct 24, 2018 · The raw materials that make up the feed arrive at the factories in different formats and grain sizes (cereals, flours, grain legumes, etc.). All of these elements must be ground to the proper particle size for subsequent mixing and ‘cooking’ with the extrusion process. To carry out this process, the most common method is to use hammer mills.

Aquatic Fish Feed Pellet Production Plant Floating Fish Feed Production Line Machinery Price , Find Complete Details about Aquatic Fish Feed Pellet Production Plant Floating Fish Feed Production Line Machinery Price,Sinking Fish Feed Pellet Machine,Aquatic Fish Feed Pellet Production Plant,Floating Fish Feed Production Line Machinery Price from Feed Processing Machines Supplier or Manufacturer

replacement Pump of Fish Feed Line / Floating Fish Feed Extruder Manufacturer data list; No. d: D: C: B: Diametro esterno: Diametro del foro: Weight: NN3068: 340 mm: 520 mm: 1620 kN: 133 mm - - 102 Kg: QVVC19V308SB