We have two types of fish feed extruder, dry type and wet type model fish feed machine. Our machines can produce both floating and sinking fish feed pellets. Moreover, you can change extrusion degree to influence floating time. As a professional Fish Feed Machine Manufacturer,Lima has rich experience and solutions in fish feed making.

.jpg)

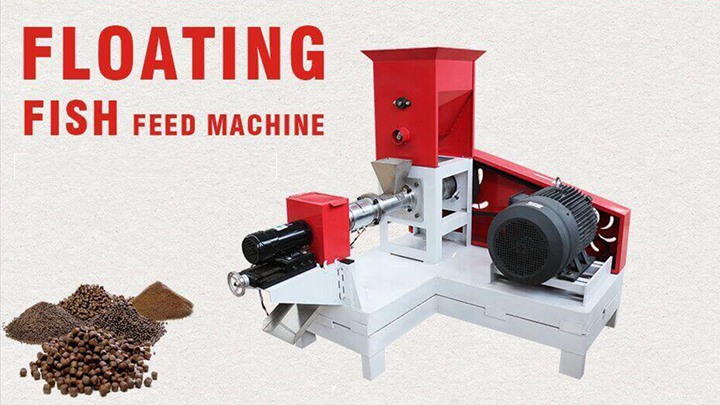

Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab, cat, dog and etc. Grain materials employed in fish feed pelletizer are such as wheat, soybean, cake and other leftovers and etc., moreover puffing pellets produced by the pellet machine can float on the water surface without dissolution

Apr 21, 2022 · In some cases the fish will grow faster, the feed coefficient will be lower, especially for smaller individual fish, tilapia and carp. 4.Excessive feeding should be strictly avoided. The sign of over feeding is that the remaining feed was not eaten by fish after feeding for more than 10 minutes.

Extruder for Animal Feed - Fish, Cats and Dogs. Extruder for Animal Feed - Fish, Cats and Dogs Main engine: 15kw | Cutting knife motor: 400w | Power motor: 400w | Production: 100-200kg/h | Machine dimensions: 1300x1200x1200mm | Machine weight: 500kgs

With fish growing, food to feed will be gradually reduced to around 250g. When their weights reach to about 500g, Tilapia enter fastest growth period. So feed quantity should be 1%-2% of that of total fish and protein content should be above 25%. Feeding way will be the following: feeding twice in one day and two periods: 8am-9am and 3pm-4pm.

.jpg)

The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, Wet type Sinking and Floating Fish Feed Extruder is a preferred choice for medium or large size feed processing factory and aquaculture farm. Advantages of Floating Fish Feed Extruder. Feeding evenly and constantly: Flat-bottomed scraper

Before the tilapia body reaches 150 grams, the protein content should be 32%~35% of the feed, daily feeding amount is 3%~5% of tilapia total weight. Rich water cultivation can also be used, relying on animal waste to cultivate biological feed fish, generally spread manure once a week, 100kg-150kg each Mu(about 666m3).

How to make tilapia fish feed - Fish Feed Extruder Machine Price Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish,

With a fish feed pellet extruder, you can make floating fish feed pellets conveniently from common materials at low cost. Feed is available in a variety of sizes ranging from fine crumbles for small tilapia to large (1/2 inch or larger) pellets.

Sep 24, 2019 · Floating fish feed pellets are ideal for tilapia, which feeds on the surface layer of water. Commercial fish feed particles are produced by extruding (floating or buoyant) or pressure settling (sinking) feed. Both floating and submerged feed particles can produce satisfactory growth, but some fish prefer to float while others prefer to sink.

TILAPIA FISH FEED. Raanan Fish Feed offers a wide range of feeds. We formulate diet adapted to all the stages or production conditions: from extensive ponds to high intensive cages or RAS. We adapt our formulation to different feeding managements, practices and concepts. The proper extrusion of the raw material and the balanced formulation of

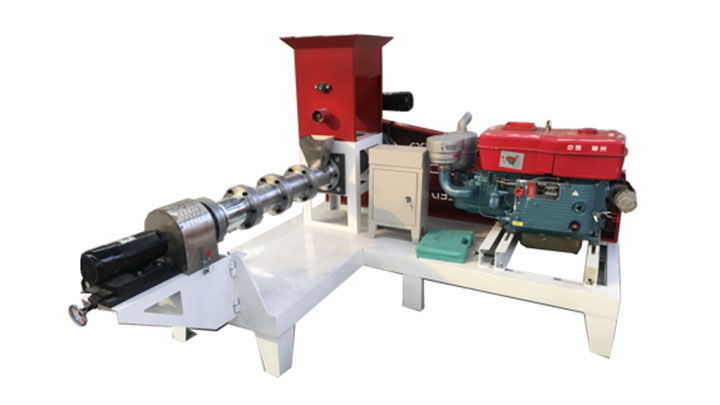

Jun 28, 2022 · Diesel Engine Fish Feed Extruder This floating fish feed machine is driven by a diesel engine and is widely used in the production of aquatic feed pellets such as fish, catfish, tilapia, shrimp, and crab etc. The produced fish feed pellets can float on the water surface and do not dissolve for more than 12 hours.

.jpg)

The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

.jpg)

The Difference between Dry-way and Wet-way Fish Feed Exturder 1:Different production processes According to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity), it is divided into dry expansion and wet expansion.

.jpg)

Jul 04, 2022 · Tilapia Feed Extruder Machine Floating Fish Feed Pellet Tilapia Feed Extruder Machine Floating Fish Feed Pellet Machinery in Shandong, China TSE65, 100kg/h-150kg/h / TSE70, 200kg Tel:+8619337889051lima37@limamachinery.com