Fish feed extruder Thailand which is designed for Thailand fish farmers to make farm-made fish feed from local feed raw materials can help the development of low-cost fish feeds program. Fish feed extruder Thailand can be used to make nutritious aquatic feed pellets for tilapia, catfish, shrimps, etc and the size of fish feed pellets can be adjusted according to Thailand fish farmers’ need from 0.9mm to 12mm and both floating fish feed pellets and sinking fish feed pellets can be made by

.jpg)

2. Application and features of Floating fish feed pellet extruder machine: 1. The finished pellets can keep floating more than 12 hours without pollution to water. 2. The floating fish feed pellet extruder machine can make pellet from Φ0.6 mm-20mm just by changing the mold. 7. Spare parts and package of the fish feed extruder mill: 8.

Floating fish feed food making pellet extruder machine for fish farming For Sale Brazil: 5: SEREN 220V/380V poultry floating fish feed machine fish feed extruder Process In Nigeria: 6: 40-50kg/h floating fish feed extruder machine for family use Sale In United Arab Emirates

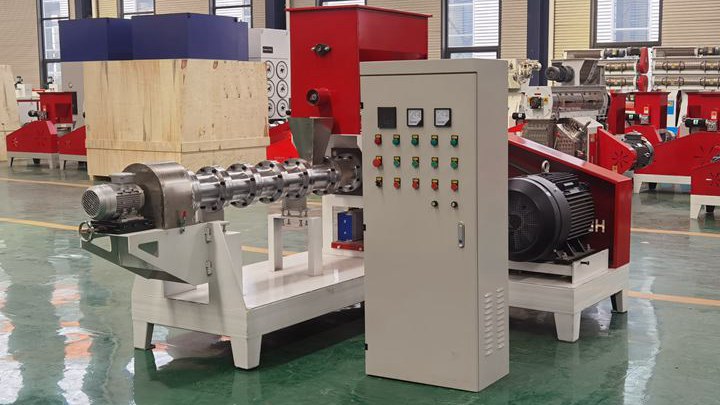

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

.jpg)

Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish, which helps adjust feeding speed to help the fish grow healthily. Feeding speed also depends on the fish’s diet.

.jpg)

Tilapia Fish Manufacturers and Suppliers. eWorldTrade.com provides 90 products, Manufacturers and Suppliers from Bangladesh, Brazil, Canada, China, Denmark and Egypt. . You have multiple options to select like Quality Tilapia Fish Scale, BLACK TILAPIA, fresh fish and Fish. You can get Tilapia Fish in bulk quantity.

.jpg)

Tilapia and Shrimp Feed Making in Brazil - Fish Feed Extruder Tilapia feed formulation mainly contains the following ingredients: bran chaff feed, oil cake feed, amphibious plant feed, pomace feed and Cereal feed, animal feed and compound feed.

Sourcing Guide for Tilapia Fish Feed Extruder: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that suppl

4.According to your requirement and production scale,pet food extruder can be classified into dry type machine and wet type machine. accoriding to your needs , we can give you the best recommedation . 5.It can produce different shapes feed for fish, dog, cat etc. Raw Materials

Made in Thailand Fish Feed Directory Tilapia Fish Feeds 2 ... Fish Feed Extruder Suppliers.

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

Popular fish feed extruder machine / tilapia fish feed pellet making Popular fish feed extruder machine / tilapia fish feed pellet making machine in China,US $ 2500 - 30000 / Set, New, Henan, China (Mainland), Allance fish feed...

About 37% of these are fish meal, 21% are fish, and 3% are feed processing machines. A wide variety of tilapia fish feed options are available to you, There are 31 tilapia fish feed suppliers, mainly located in Asia. The top supplying country or region is Thailand, which supply 100% of tilapia fish feed respectively.

.jpg)

Take the extrusion pellet surface water to avoid the adhesion and get a good shape pellet FAQ. What about the starch content requirement for floating and sinking fish extrusion feed? Floating feed: starch content≥20%; Sinking feed: starch content≥10%. What about the fine degree request of extruded raw material?

.jpg)

3. Extrusion by fish feed extruder: under the pressure-tight condition, material in high temperature will be formed into pellets by shaping mould. Dry type feed extruder is popular in aquafeed production. 4. Drying: Final pellets from fish feed extruder are moist in high temperature, so use pellet dryer to remove moist and heat. 5.