China Food Extruder Machine Suppliers, Manufacturers Diesel Engine Floating Fish Feed Machine. Diesel dry-way type floating fish feed pellet extruder machine mainly use maize, fis+86 19337889051

Professional Manufacturer Tilapia Fish Feed Pellet Extruder Machine Project Price List; Product : Quantity: Min Price ($) Max Price ($) Fish Feed Extruder Poultry Animal/Pet Food Pellet Mill Machine: 1 Set : US$1334: US$5262: Factory Price Floating Sinking Aquatic Feed Machine Freshwater Fish Feed Extruder Feed Pellet Granulator Production Line

.jpg)

The difference between feed pellet machine and feed extruder . Feed pellet machine: feed pellet machine, widely used in large, medium and small aquaculture, grain feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing Factory use.Feed extruder: This series of dry and wet extruders are

Code. 6363. Fresh water Fish Feed (3mm) 6383. Prestarter (1.5 - 2.0mm) Fish Size. All stage. < 5 g - 20 g.

.jpg)

At present, there are two kinds of artificial diets in tilapia feed, one is ordinary pellet and the other is extruded feed pellets. 0.75 to 1 kilograms tilapia feed produced by fish feed extruding machine can feed 0.5kg tilapia. In the production of ordinary pellets, the tempering temperature should be controlled between 80℃~95℃.

The raw materials which can be used as formulation are corn flour, soy flour, tapioca flour, etc. Most of them are common and easy to find in Malaysia. Right now, the estimated pelleted feed requirement is nearly 700,000 tonnes, includes nearly 170,000 tonnes for marine fish. But out of the total amount, only 100,000 tonnes were produced

tilapia fish feed extruder manufacturers/supplier, China tilapia fish feed extruder manufacturer & factory list, find best price in Chinese tilapia fish feed extruder manufacturers, suppliers, factories, exporters & wholesalers quickly on LimaFeedPelletizer.com.

.jpg)

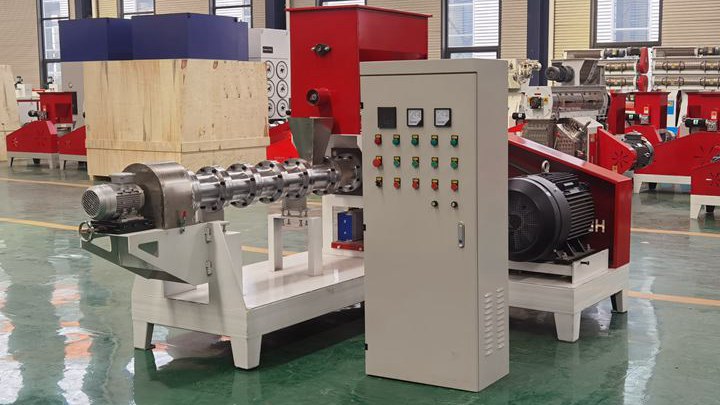

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

Tilapia from Malaysia - Free to use unique search engine of reliable, genuine and verified companies, suppliers, exporters, sellers, manufacturers, factories, traders, tradeleads of products and services from all over the world.

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

Farm-made feeds are not a major feed input in tilapia farms in Malaysia. They are made and used as supplement to commercial tilapia feed by small and medium sized tilapia farmers. In order to reduce feed production cost, farmers can choose dry type fish feed extruder to make own tilapia feed from local feed ingredients.

.jpg)

Floating Fish Feed Extruder Suppliers & Manufacturers & Factory - Buy Good Pfish feed Floating Fish Feed Extruder . Floating fish feed extruder machine is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog,cat etc.

.jpg)

Malaysia Tilapia Fish Feed Pellet Mill, Wholesale Various High Quality Malaysia Tilapia Fish Feed Pellet Mill Products from Global Malaysia Tilapia Fish Feed LEARN MORE Malaysia flat die animal fish feed pelletfish pellet machine – Pet ...

.jpg)

Amazing tilapia feed machine At Fabulous Offers –Lima.com. 60-80kg/h Dry type floating fish feed extruder machine extruder tilapia feed floating floting fish feed machine. US $1640. 4 YR. Add to Favorites. 500-600kg/h small scale fish feed pellet making production machine drying floating tilapia fish feed machine in China. US $9645. 4 YR.

.jpg)

Generally the compound feed of Tilapia are in two types: pelleted feed and extruded feed. To produce pelleted feed, the conditioning temperature should be controlled between 80-95℃. With sufficient conditioning period, good gelatinization can be achieved.