.jpg)

1.Ponds should be selected where there is sufficient water, good water quality, no pollution, and convenient drainage. The breeding of adult tilapia has no special requirements for ponds. General farming ponds can be used for breeding. The area is 8-10 mu, and the maximum is no more than 20 mu. The water depth is generally 1.5 to 2 meters.

.jpg)

Compound feed is widely applied in Tilapia farming in the world. Compound fish feed can be made depending on the following factors: feed sources, Tilapia nutrient requirements and raw material nutrient content. Whether in pond farming or in intensive farming, the addition of mineral salts is of importance for making fish feed. III.

.jpg)

Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish, which helps adjust feeding speed to help the fish grow healthily. Feeding speed also depends on the fish’s diet.

.jpg)

Processing » Extruders » tilapia fish farming equipment fish feed making extruder machine in Zhengzhou, China Fish feed packing: 0-25KG per bag. Feed pellet:

.jpg)

Tilapia extruder floating fish feed extruder fish feed machine in Henan, China Farms, Home Use, Retail. Place of origin: Henan, China. Voltage: 220V/380V or ...

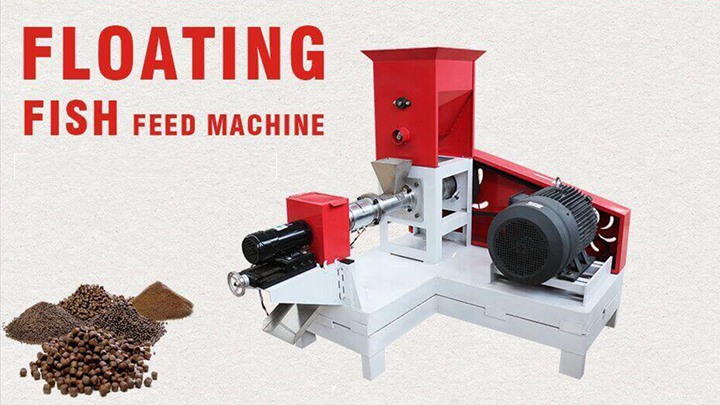

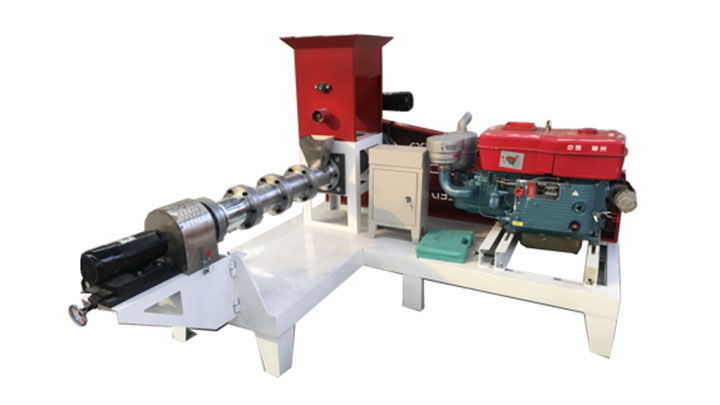

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

.jpg)

Applicable industries: Farms, Fish ground, pet feed factory, Place of origin: Henan, China, Voltage: 220v/380v, Dimension(l*w*h): Floating fish feed extruder for tilapia feed in Zhengzhou, China USD ($)

Animal Aquarium Pet Dog Cat Monkey Fox Bird Tilapia . Dry Nutritional Dog Food Machine Pet Food Extrusion Machine Extruder Production Line: 1 Set : US$1153: US$6399: Best Price Floating Sinking Fish Feed Pellet Making Machine Fish Food Machine Aquatic Feed Bulking Device Production Line: 1 Set : US$1989: US$5206: Fried Potato Chips Frozen French Fries Food Machine Production Line: 1 Set : US$1414

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

tilapia fish feed extruder manufacturer/supplier, China tilapia fish feed extruder manufacturer & factory list, find qualified Chinese tilapia fish feed extruder manufacturers, suppliers, factories, exporters & wholesalers quickly on LimaFeedPelletizer.com., page 2

Tilapia and Shrimp Feed Making in Brazil - Fish Feed Extruder Tilapia feed formulation mainly contains the following ingredients: bran chaff feed, oil cake feed, amphibious plant feed, pomace feed and Cereal feed, animal feed and compound feed.

Good Market in Sri Lanka animal feed pellet making machine. Shandong Leader Machinery Mobile : 18660125156 Website : www.digit-life.com Telephone : 86-05331-85064681 Mail : info@ldfoodmachine.com Fax : 86-05331-85064682

.jpg)

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

.jpg)

Growing Conditions for Tilapia. During the growth phase, you need to feed your fish and maintain favorable environmental conditions. When the characteristics of water are kept within the optimal range, the growth effect is the best. For tilapia, the recommended water chemistry values are as follows: Temperature: 80-100°F, 85°F is optimal.

3. Extrusion by fish feed extruder: under the pressure-tight condition, material in high temperature will be formed into pellets by shaping mould. Dry type feed extruder is popular in aquafeed production. 4. Drying: Final pellets from fish feed extruder are moist in high temperature, so use pellet dryer to remove moist and heat. 5.