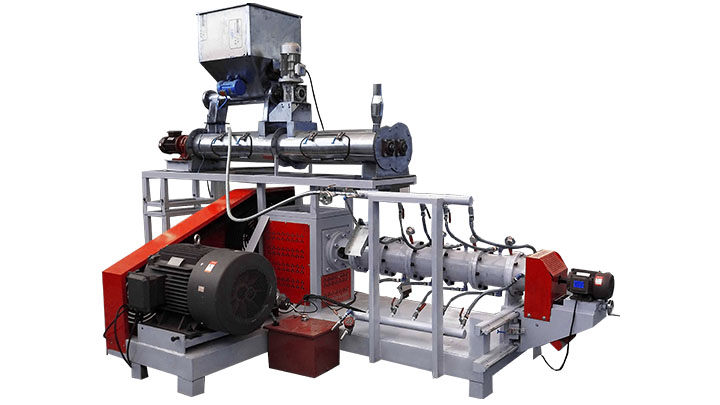

Cost-efficient Fish Feed Machine of Top Quality. Introduction to Dry Type Fish Feed Extruder Dry type fish feed extruder, also called fish feed pellet mill, is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc.The final feed pellets have unique shape and good taste, high nutrition and smooth textures.

.jpg)

Growing Conditions for Tilapia. During the growth phase, you need to feed your fish and maintain favorable environmental conditions. When the characteristics of water are kept within the optimal range, the growth effect is the best. For tilapia, the recommended water chemistry values are as follows: Temperature: 80-100°F, 85°F is optimal.

.jpg)

Jun 29, 2022 · cost Tilapia fish feed extruder machine kenya Aug 26, 2021 · Stainless Steel 100-250kg/h diesel-type wet-way fish feed Automatic Extruded Dog Food Feed Pellet Making LiMa fish feed machine. 2021-6-16 · Automatic Kibble fish Dog Monkey Fox Tilapia Floating Fish Feed Pellet Production Machine fish feed Food Mill Processing Making Extrusion Line Pfish feed US $18,000-56,000 / Set Production Line Dry

.jpg)

Floating fish feed food making pellet extruder machine for fish farming For Sale Brazil: 5: SEREN 220V/380V poultry floating fish feed machine fish feed extruder Process In Nigeria: 6: 40-50kg/h floating fish feed extruder machine for family use Sale In United Arab Emirates

Fish Farm tilapia floating fish feed machine extruder in Dezhou, China DLG120 Fish Feed Pellet Making Extruder machine. ... Condition: new. Applicable industries ...

Applicable industries: Manufacturing Plant, Farms, Place of origin: Shandong, China, Voltage: According to your triple phase voltage,

.jpg)

Tilapia fish feed extrusion process machine Extruders are the machinery accustomed manufacture extruded pet food, (floating) extruded aquatic feeds and extruded animal feeds. The extrusion cookery method, as a result of it causes a high level of gelatinisation of starches, ends up in feeds with smart water stability.

.jpg)

Application of extruder pellet machine. 1. Aquatic feed pellet for fish, catfish, tilapia, tilapia fish, shrimp, crab, etc.Both floating and sinking feed pellets. The floating time can be adjusted by the different puffing degree.Main use:

Tilapia fish feed extrusion process machine Extruders are the machinery accustomed manufacture extruded pet food, (floating) extruded aquatic feeds and extruded animal feeds. The extrusion cookery method, as a result of it causes a high level of gelatinisation of starches, ends up in MORE

At present, there are two kinds of artificial diets in tilapia feed, one is ordinary pellet and the other is extruded feed pellets. 0.75 to 1 kilograms tilapia feed produced by fish feed extruding machine can feed 0.5kg tilapia. In the production of ordinary pellets, the tempering temperature should be controlled between 80℃~95℃.

Feed ingredients of plant and animal origin used in the formulation of tilapia feeds with their general nutritional values and other relevant information are provLIMAed in Tables 10-11-12.The maximum inclusion level of each feedstuff that can be used in tilapia feeds is dependent on several factors such as the level of dietary protein, how the feedstuff was processed, life stLIMAe

4.According to your requirement and production scale,pet food extruder can be classified into dry type machine and wet type machine. accoriding to your needs , we can give you the best recommedation . 5.It can produce different shapes feed for fish, dog, cat etc. Raw Materials

.jpg)

new design tilapia fish feed extruder for sale with easy-to-use parts graphics, giving you the ability to check parts availability, Castor Oil Plant Machine pricing, examine remanufactured 5.76 Inch | 146.304 Assembly Width options.

.jpg)

Compound fish feed can be made depending on the following factors: feed sources, Tilapia nutrient requirements and raw material nutrient content. Whether in pond farming or in intensive farming, the addition of mineral salts is of importance for making fish feed. III. Compound Feed of Tilapia

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.