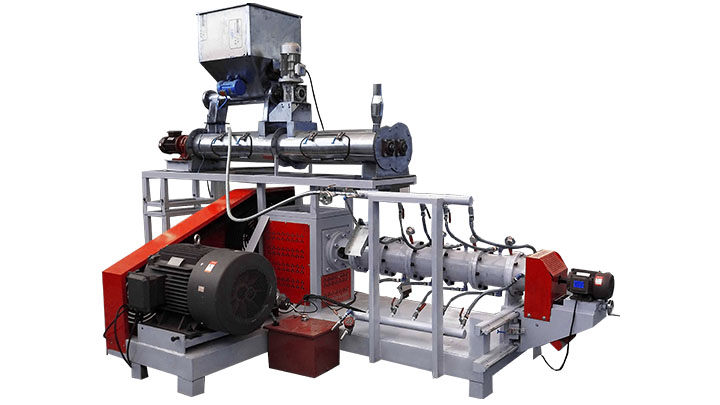

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

.jpg)

Feed ingredients of plant and animal origin used in the formulation of tilapia feeds with their general nutritional values and other relevant information are provLIMAed in Tables 10-11-12.The maximum inclusion level of each feedstuff that can be used in tilapia feeds is dependent on several factors such as the level of dietary protein, how the feedstuff was processed, life stLIMAe

.jpg)

Tilapia and Shrimp Feed Making in Brazil - Fish Feed Extruder Tilapia feed formulation mainly contains the following ingredients: bran chaff feed, oil cake feed, amphibious plant feed, pomace feed and Cereal feed, animal feed and compound feed.

.jpg)

High Efficiency Low Price Puffed Tilapia Food Extruder Equipment/floating Fish Feed Pellet Making Machine Find pellet making machine with free shipping, fast delivery and free return online. Find products of Food Processors with high quality at AliExpress.

Promotion tilapia feed extruder fish pelleting mill in Henan Used 3.5" Cincinnati Milacron Side Feed Extruder, 30:1 L/D Ratio, 75 HP in United States. Manufacturer: Cincinnati Milacron; Used 3.5" Cincinnati Milacron Side Feed Single Screw Extruder Model Apex 3.5 30:1 L/D Ratio, 30:1 L/D Special Screw for MuCell Material Side Port Feed Throat

Improving Floating Fish Feed in Bangladesh ☞ Extrusion technology is mainly used for producing floating feed for tilapia, which accounts for around 40–50% of total tilapia feed production and retails for 7–10 BDT/kg (USD0.09–0.128/kg) more than sinking feed.The production rate of grower feed is 1–2 tonnes/hour greater than that of starter feed, while energy consumption in machine

FAO: Feed formulationIn Thailand, a typical feed formulation for herbivorous fish may include fishmeal (16 percent), peanut meal (24 percent), soybean meal (14 percent), rice bran

Model :LM80 Capacity (kg/h):200-300kg/h Main power (kw):22kw Feeder power (kw):0.6kw Screw Diameter (mm):Φ80 Cutter power (kw):0.6kw Machine size (mm):4000*2100*1900mm

low price Haddock fish feed extruder machine nepal- Lima low price Haddock fish feed extruder machine nepal Floating Fish feed pellet machine using for aquaculture and animal husb+86 19337889051lima37@limamachinery.com

Water quality: The extruded floating fish feed will not dissolve in the water for a long time. The floating time of high-quality floating fish feed can be as long as 12 hours, and it is easy to observe and control the bait, reducing or avoiding the . 400-500kg/h Floating Fish Feed Extruder Machine Fish Feed

Floating fish feed food making pellet extruder machine for fish farming For Sale Brazil: 5: SEREN 220V/380V poultry floating fish feed machine fish feed extruder Process In Nigeria: 6: 40-50kg/h floating fish feed extruder machine for family use Sale In United Arab Emirates

Compound feed is widely applied in Tilapia farming in the world. Compound fish feed can be made depending on the following factors: feed sources, Tilapia nutrient requirements and raw material nutrient content. Whether in pond farming or in intensive farming, the addition of mineral salts is of importance for making fish feed. III.

Tilapia Feed Pellet Making Machine - Buy Tilapia Feed Tilapia Feed Pellet Making Machine , Find Complete Details about Tilapia Feed Pellet Making Machine,Tilapia Feed Pellet Makin

.jpg)

At present, there are two kinds of artificial diets in tilapia feed, one is ordinary pellet and the other is extruded feed pellets. 0.75 to 1 kilograms tilapia feed produced by fish feed extruding machine can feed 0.5kg tilapia. In the production of ordinary pellets, the tempering temperature should be controlled between 80℃~95℃.

With this complete fish feed mill plant, you can use various materials to produce feed pellets for fish, shrimps, crab,tilapia etc. The final pellets can have different shapes. We can customize different capacities for fish farmers and fish feed manufacturers,and the cost of setting up a fish feed manufacturing plant is closely related to the