.jpg)

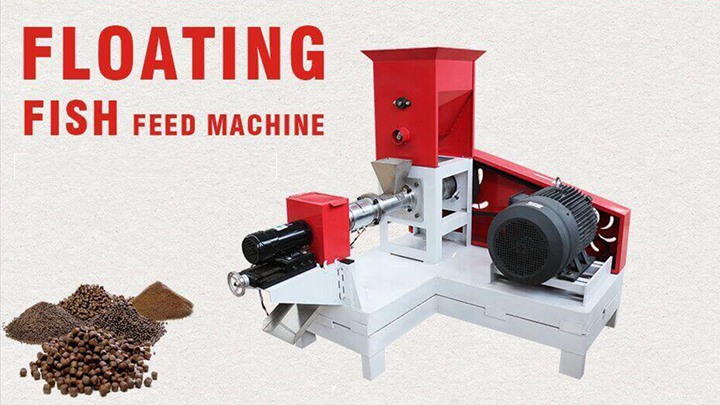

3. The kernel step of feed production is extrusion. There are two types of fish feed machines for extrusion: dry type fish feed machine and wet type fish feed machine. For feed production in Kenya, dry type fish feed extruder is recommended, due to suitable price and stable performance. Many customers cooperated with us are all satisfied with

Kenyan Fish Suppliers, Manufacturers, Wholesalers and . Specificationsfish meal for sale 1.manufacturer price 2.best price 3.protein:65% fish meal for sale Features Fish contains a variety of nutrients comprise animal tissue, maintain normal metabolism, growth, reproduction is required, has improved the utilization rate of feed and promote animal growth, improve animal disease resistance

Apr 09, 2021 · Commercial tilapia feeds are formulated, cooked, extruded, and pelletized diets typically containing 32 – 40% protein. This can be a fish meal or soy-based protein, with the former being more palatable to the tilapia fish. Floating pellets are generally recommended, as they remain on the surface until consumed.

.jpg)

Jul 12, 2021 · The status of the Kenyan fish feed industry. In semi-intensive and intensive aquaculture systems, feeds typically account for between 40–60% of production costs (Shitote et al., 2001; Ali and Jauncey, 2004; Liti et al., 2006).Contribution of 50 percent and above in the total operating cost indicates that fish feed is the most costly item in aquaculture production.

Fish Feed Extruder/Fish Feed Machine for Malaysia Fish Feed There are four main types of commercial tilapia feeds are available in Malaysia: pre-starter feeds, starter feeds, grower feeds and finisher feeds.

There are two types of fish feed machines for extrusion: dry type fish feed machine and wet type fish feed machine. For feed production in Kenya, dry type fish feed extruder is recommended, due to suitable price and stable performance. Many customers cooperated with us are all satisfied with dry type feed machine.

floating fish feed extruder machine priceShandong Leader Machinery Mobile : 18660125156 Website : www.digit-life.com Telephone : 86-05331-85064681 Mail : info@ldfoodmachine.com Fa

.jpg)

Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish, which helps adjust feeding speed to help the fish grow healthily. Feeding speed also depends on the fish’s diet.

Making Fish Food for Tilapia by Fish Feed Machine – Fish . Get Price Now! In short, the fish feed extrusion process requires a hammer mill to grind the raw materials, the mixer mixed raw materials include vitamin mineral premix and the wet fish feed extruder’s steam preconditioner and cutter head shape pellets, and finally dryer-cooler to ensure the shelf life and stability of the granules..

More specifically, the fish feed production line has capacities with 100-200kg/h, 300-400kg/h, 1t/h, 2t-4t/h and so on. Making Floating Fish Feed in Kenya – Fish Feed Extruder. There are two types of fish feed machines for extrusion: dry type fish feed machine and wet type fish feed machine. For feed production in Kenya, dry type fish feed extruder is recommended, due to suitable price and stable performance.

.jpg)

Fish Feed Production-Lima Fish fish Feed Making Machine To help fish farmers provide balanced fish feed pellets at a bargain price. As a professional fish feed machine designer and manufacturer, we have launched a series of fish feed maker,fish feed production,fish food making machine with reasonable prices and high quality according to the

.jpg)

factory Tilapia fish feed extruder machine kenya Floating Fish feed pellet machine using for aquaculture and animal husbandry. For example: catfish、Tilapia fish 、dog、tortoises、frogs and so on. Just change mould can make many different shape and size.

When the water temperature is below 15℃ or above 32℃, farmers also need to reduce feeding or stop feeding, which contributes to fish digestion, good water quality and feed cost controlling. In high temperature season, feed with high protein content is disadvantageous to fish digestion, resulting in fish disease.

.jpg)

Feeding way will be the following: feeding twice in one day and two periods: 8am-9am and 3pm-4pm. Every 15-20 days, catching 30-50 fish to calculate the average weight for analyzing Tilapia growth, which contributes to adjusting feeding rate for helping fish grow healthily. Feeding rate also depends on fish eating.

Single screw fish feed processing line can be divided into 2 types: Small Dry Type Plant and Large Wet Type Plant, in accordance with what extruder you choose. WET TYPE: Super automation control and high production efficiency, it is the best choice for medium and big sized feed mills and breeding farms.