.jpg)

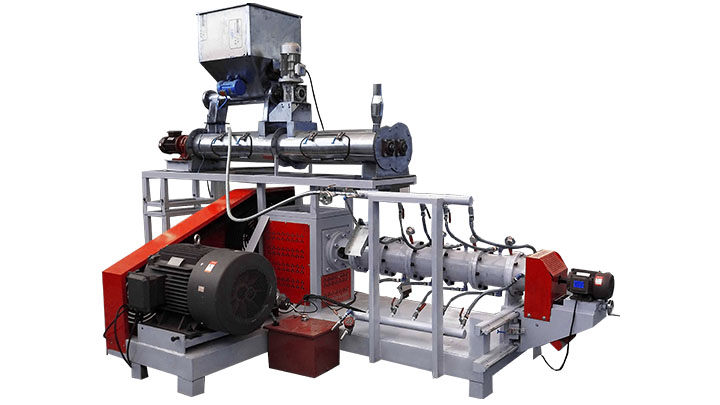

Farming equipment Automatic Tilapia Fish Feed extruder in Applicable industries: Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops, Video outgo Tel:+8619337889051lima37@limamachinery.com

Most Popular Best Quality Floating Fish Feed Pellet Machine 1. floating fish feed machine Introduction This feed extruder machine is suitable for making floating fish feed and oth+86 19337889051lima37@limamachinery.com

The proper extrusion of the raw material and the balanced formulation of nutrients improve the fish production till harvesting. High growth rate and low feed conversions improve the economical/financial results of the fish farmers. Our extruded feed is floating and allows the fish farmer to observe the behavior of the fish during time of feeding.

.jpg)

tilapia fish feed extruder-floating fish feed machineFish Feed Extruder Machine Price - Tilapia Tilapia and Shrimp Feed Making in Brazil - Fish Feed ExtruderTilapia feed formulati Tel:+8619337889051lima37@limamachinery.com

Wholesale Price fish feed pellet extrusion production line Wholesale 100-150kg/h diesel-type floating fish feed machine Congo price Wholesale Price motor-type dry-way 100-250kg/h+86 19337889051lima37@limamachinery.com

Tilapia Fish feed extruder/pet food processing machine in model: dl56 / dl65 / dl70 / dl80 / dl90 / dl95 / dl120 / dl140 / dl160 dry type fish extruder machine cost Indonesia- Li Tel:+8619337889051lima37@limamachinery.com

Generally the compound feed of Tilapia are in two types: pelleted feed and extruded feed. To produce pelleted feed, the conditioning temperature should be controlled between 80-95℃. With sufficient conditioning period, good gelatinization can be achieved.

.jpg)

Sep 24, 2019 · In general, there are two main types of tilapia compound feed. They are pellet feed and extruded feed. In order to produce pellet feed, the temperature must be controlled between 80 and 95℃. Sufficient conditioning time can produce good gelation.

.jpg)

model: dl56 / dl65 / dl70 / dl80 / dl90 / dl95 / dl120 / dl140 / dl160

.jpg)

3. Extrusion by fish feed extruder: under the pressure-tight condition, material in high temperature will be formed into pellets by shaping mould. Dry type feed extruder is popular in aquafeed production. 4. Drying: Final pellets from fish feed extruder are moist in high temperature, so use pellet dryer to remove moist and heat. 5.

.jpg)

Tilapia and Shrimp Feed Making in Brazil - Fish Feed Extruder Tilapia feed formulation mainly contains the following ingredients: bran chaff feed, oil cake feed, amphibious plant feed, pomace feed and Cereal feed, animal feed and compound feed.

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

.jpg)

Call +91-8046046033. Contact Supplier Request a quote. Fisher Gold Fish Feed, Packaging Size: 20 Kg And 35 Kg ₹ 1,350/ Kg. Get Quote. Aquatic Fish Feed Floating, Packaging Type: Plastic Bag ₹ 785/ Kg. Get Quote. Sinking Fish Feed

Tilapia Feed Formulation and Feeding - Fish Feed Extruder Feeding way will be the following: feeding twice in one day and two periods: 8am-9am and 3pm-4pm. Every 15-20 days, catching 30-50 fish to calculate the average weight for analyzing Tilapia growth, which contributes to adjusting feeding rate for helping fish grow healthily.

Apr 09, 2021 · Commercial tilapia feeds are formulated, cooked, extruded, and pelletized diets typically containing 32 – 40% protein. This can be a fish meal or soy-based protein, with the former being more palatable to the tilapia fish. Floating pellets are generally recommended, as they remain on the surface until consumed.