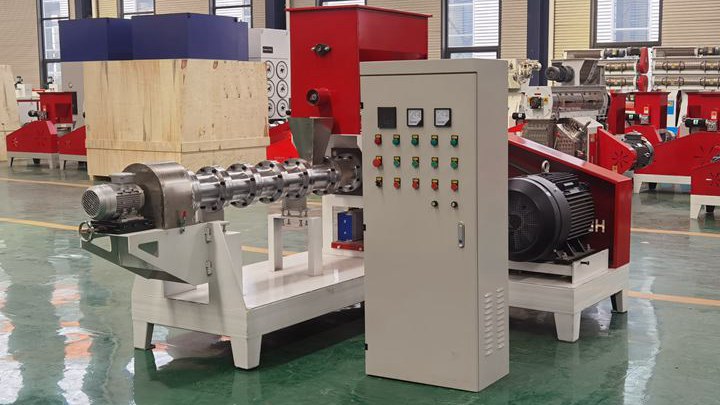

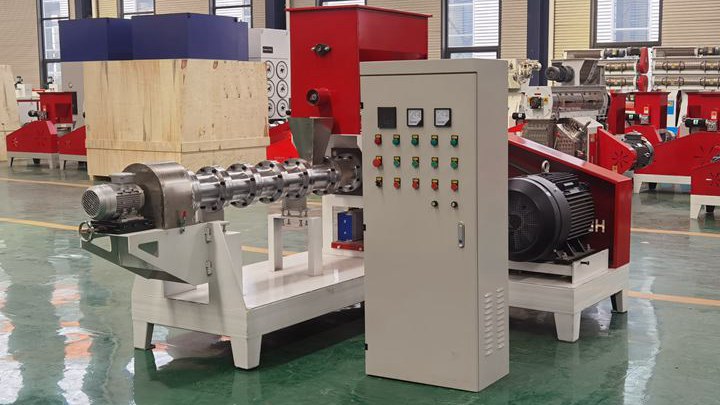

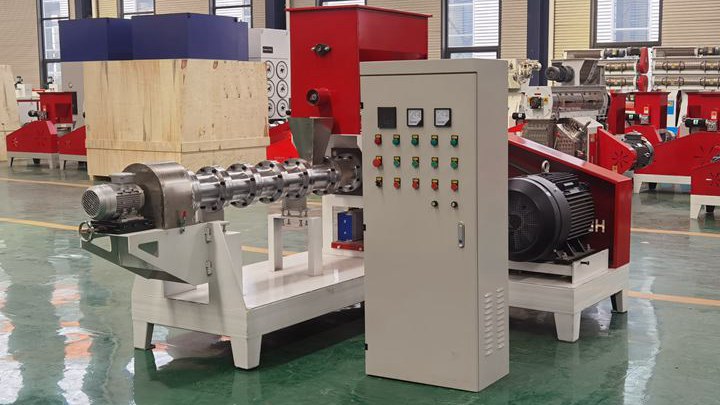

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

Automatic High Quality Dry Type Floating Fish Feed Extruder Machine From China Product Description: With the development of the society, aquaculture feed gradually attracts people's eyes. So aquaculture feed is a big market and many people

With a fish feed pellet extruder, you can make floating fish feed pellets conveniently from common materials at low cost. Feed is available in a variety of sizes ranging from fine crumbles for small tilapia to large (1/2 inch or larger) pellets. The pellet size should be approximately 20-30% of the size of the tilapia mouth gape.

.jpg)

Factory Made Tilapia Fish Feed Extruder/pet Food Processing Machine Pet Line 5000kg Extruder Making , Find Complete Details about Factory Made Tilapia Fish Feed Extruder/pet Food Processing Machine Pet Line 5000kg Extruder Making,Tilapia Fish Feed Extruder/pet Food Processing Machine,Pet Food Line,5000kg Extruder Pet Food Making from Pet Food Processing Machines Supplier or Manufacturer-Henan

.jpg)

The proper extrusion of the raw material and the balanced formulation of nutrients improve the fish production till harvesting. High growth rate and low feed conversions improve the economical/financial results of the fish farmers. Our extruded feed is floating and allows the fish farmer to observe the behavior of the fish during time of feeding.

Fish feed pellet making machine like tilapia fish feed machine and Malaysia Fish Feed Animal Feed Production Line / Plant, Feed Milling Equipment Price. LEARN MORE

Dry type fish feed extruder - Fish Feed Machine Dry type fish feed extruder, also called fish feed pellet mill, is widely used for For feeds of fish and shrimp, the floating time on water surface can be ... extruder has become an ideal for small and medium fish farm (catfish, tilapia, shrimp etc.)...

Mar 11, 2014 · It is well recognized that extruded floating feed has many benefits for tilapia and other surface feeding species – less feed wastage, better water quality, faster growth rates. But until recently, extruders only came with relatively high capacities at 5 or 10 mt/hour, putting them out of reach of smaller aquaculture operations.

.jpg)

Feeding way will be the following: feeding twice in one day and two periods: 8am-9am and 3pm-4pm. Every 15-20 days, catching 30-50 fish to calculate the average weight for analyzing Tilapia growth, which contributes to adjusting feeding rate for helping fish grow healthily. Feeding rate also depends on fish eating.

.jpg)

Floating Fish Feed Manufacturing Process. Selection of Raw Material. When selecting raw materials for fish feed processing, remember that the final product must be stable in water. The main nutrients are starch, with 10% to 15% of feed for sunken fish and over 20% of feed for floating fish. The starch content is generally between 5% and 60%.

Tilapia fish feed extrusion process machine Extruders are the machinery accustomed manufacture extruded pet food, (floating) extruded aquatic feeds and extruded animal feeds. The extrusion cookery method, as a result of it causes a high level of gelatinisation of starches, ends up in feeds with smart water stability.

.jpg)

Take the extrusion pellet surface water to avoid the adhesion and get a good shape pellet FAQ. What about the starch content requirement for floating and sinking fish extrusion feed? Floating feed: starch content≥20%; Sinking feed: starch content≥10%. What about the fine degree request of extruded raw material?

.jpg)

Apr 09, 2021 · Commercial tilapia feeds are formulated, cooked, extruded, and pelletized diets typically containing 32 – 40% protein. This can be a fish meal or soy-based protein, with the former being more palatable to the tilapia fish. Floating pellets are generally recommended, as they remain on the surface until consumed.

Diesel engine fish feed extruder is driven by a diesel engine and operates on this basis. The capacity is from 30 kg/h to 2 tons per hour. It is most favoured by African customers, such as Nigeria, Kenya,Uganda, because of the lack of elctricity in their locals. Cheaper than Motro driven ones. Contact Us Now! Fish Feed Pellets Extruder in Nigeria.

.jpg)

Widely Use Salmon Feed Extruder Carp Feed Making Machine May 21, 2017 ... Dry type fish feed extruder, also called fish feed pellet mill, is widely used for For feeds of fish and shrimp, the floating time on water surface can...