.jpg)

Statistics show that although the production capacity of the Nigerian aquafeed industry declined in the 1980s, it rose sharply in 2000 when the production capacity of 35570 tons of aquatic feed was recorded, while the output was 10,760 tons. It is estimated that Nigeria’s aquatic feed production in 2015 was 647,750 metric tons.

DGP50 hydrophonic fodder system floating fish feed extruder machine in nigeria, US $ 1625 - 4165 / Set, Manufacturing Plant, Farms, LIMA Use, VLIMAeo technical support, fish feed machine support, Spare parts, Nigeria.Source from Henan Lima Machinery Manufacture Co.,Lima on Lima.

Jiaozuo Double Eagle Home Use Automatic fish bird feed pellet extruding making machine: N32,800 – N32,500. Yingwang Mini floating fish feed pellet making machine/chicken feed making machine/fish feed machine: N606,000 – N680,000. Small Animal Pet Catfish Food Making Extruder Floating Fish Feed Pellet Machine: N41,000 – N67,000.

China 2000kg/H Floating Fish Feed Extruder Machine Pet Food Processing Machines, Find details about China Automatic Floating Fish Food Production Line, Automatic Fish Food Production Line from 2000kg/H Floating Fish Feed Extruder Machine Pet Food Processing Machines - Shandong Saibainuo Machinery Co., Ltd.

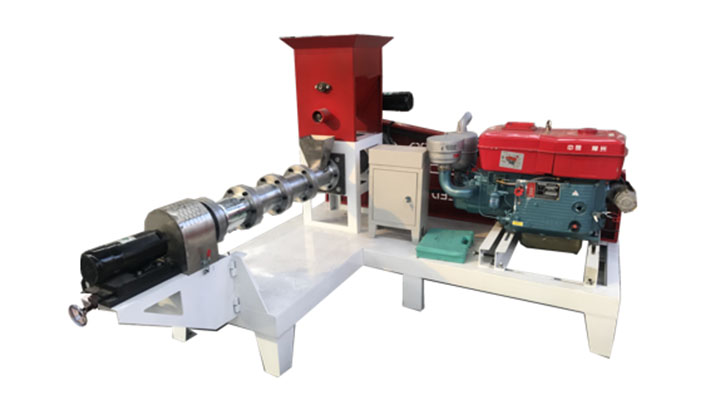

The feed pelleting machine is locally fabricated in Nigeria, which is operated by diesel engine, electricity powered machine or manually. It consists mainly of hopper, housing, screen, base stand and etc..

.jpg)

Jul 20, 2021 · After our survey of both offline and fish feed machine vendors, we have come up with the pfish feed list below: Cecle Animal floating fish chicken poultry feed pellet mill making machine, grinder mixer machine: N163,000 – N819,000. WDL fish food processing floating fish feed mill pellet extruder machine: N90,000 – N300,000.

floating fish feed pelletizer- - Lima Fish Feed MachineMar 18, 2022 · The sinking fish feed pellets are super-efficient and come with unequaled deals. Fish Feed Processing Line –+86 19337889051

.jpg)

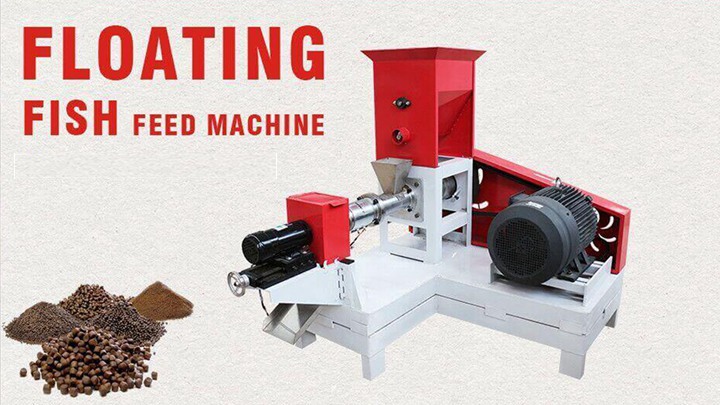

The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, Wet type Sinking and Floating Fish Feed Extruder is a preferred choice for medium or large size feed processing factory and aquaculture farm. Advantages of Floating Fish Feed Extruder. Feeding evenly and constantly: Flat-bottomed scraper

Floating fish feed pellets making solution in Nigeria. • Collect raw feed stuffs mentioned above. • Weigh the required quantity of various feed ingredients according to the formulation specification. • Grind ingredients into powdery form with a feed hammer mill. • Feed the powdery ingredients into fish feed extruder.

.jpg)

More specifically, the fish feed production line has capacities with 100-200kg/h, 300-400kg/h, 1t/h, 2t-4t/h and so on. Fish Feed Made by Locally. Fish feed can be divided into sinking fish feed and floating fish feed according to their buoyancy. In Nigeria’s fish farming industry, there is a great demand for floating fish feed.

Jul 07, 2022 · This floating fish feed machine is driven by a diesel engine and is widely used in the production of aquatic feed pellets such as fish, catfish, tilapia, shrimp, and crab etc. The produced fish feed pellets can float on the water surface and do not dissolve for more than 12 hours. According to the processing technology, fish feed extruders can

.jpg)

Fish feed making machine is also named fish feed extruder, and it is used for processing for dogs and cats (pet food), birds, piglets, frogs, sinking and floating aquatic feeds for fish. See the feedback–floating fish feed production line from our customer:

.jpg)

Pellets can be produced from both pelletizer and extruder. Pelleting was introduced into Europe about 1920 and into the United States feed industry. floating & sinking fish feed making machine processing . Feb 26, 2022 · Jinan Sunward Machinery Co.,Ltdalice@cnsunward.com +8615689697595. nigeria high quality floating fish feed extruder machine

.jpg)

Floating Catfish Feed Pellet Production in Nigeria. Fish feed pellets from pellet making machine need to lower high moisture and temperature. So dryer should be equipped in the production line. The best and most gentle drying is obtained with a low temperature dryer, 80℃, and long drying time. Here the multi-layer dryer is recommended for best drying quality.