Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

5、Nov 19, 2016 — I need help on extrusion of fish sinking feed .I reach 50:50 of sinking and i need 99 % but i just can not make feed to sink is it from 73 answers · Top answer: Denis; Extrude Fish Feed is one of the most difficult application for an extruder/expander due to the nature of the ingredients and also due ...

.jpg)

Feed Pellet Machine; Feed Pellet Line; Tel: +86-519-86083312 Phone: +8613733816811 Email:info@bestpelletmachinery.com manager@bestpelletmachinery.com Add: No.69 Hongchang Road, Kunlun Street, Liyang City, Jiangsu Province, China

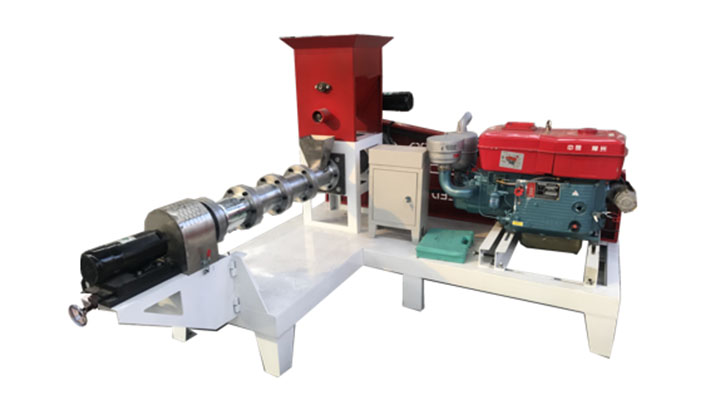

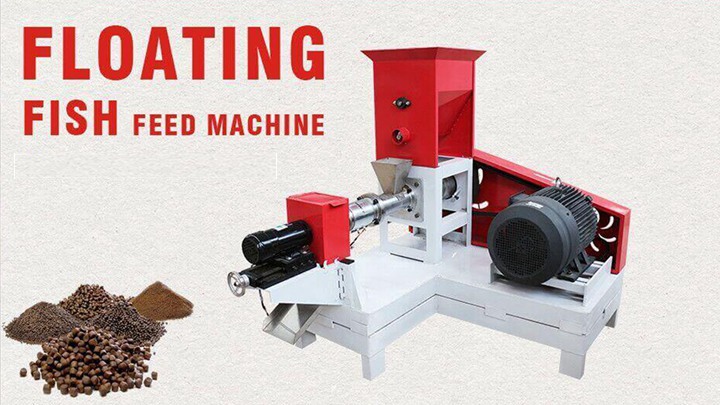

Extruded Floating & Sinking Fish Feed Processing and Briefly, fish feed extrusion process requires a hammer mill to grind raw materials, mixer to blend raw materials including vitamin-mineral premix, the wet type fish feed extruder with steam preconditioner (yes, steam is equired for quality pellets) and cutter head to

China Automatic Dry Floating Sinking Animal Feed Pet Fish Dog Cat Food Pellet Processing Line Making Machinery, Find details about China Cat Puppy Food Machine, Cat Puppy Food Extruder from Automatic Dry Floating Sinking Animal Feed Pet Fish Dog Cat Food Pellet Processing Line Making Machinery -LimaFeedMachinery Co., Ltd.

4、how to make floating fish pellets,fish feed extrusion process Extrusion, including dry extrusion and wet YouTube · Victor Pellet Mill · Dec 6, 2017; 5、by P Vijayagopal · 2004 · Cited by 15 — fish feed or a pet food utilizing a wet waste as one of the raw mateirals.

Product Description of fish feed pellet extruder: 1.Automatic pet food production line using flour, corn meal, soybean meal, meat meal, fish meal, bone meal as raw materials. 2.The automatic mixing system achieve automatic and scientific mixing, 3.twin screw extruder extrusion produce various shapes

nutrients lost during the extrusion process. Extrusion involves the plasticizing and cooking of feed ingredients by a combination of pressure, heat and friction. Steam pelleting uses heat, moisture and pressure to create larger feed particles. Recently, the question has been asked, “how much or what percentage of a floating feed should float?”

Customer Case Of Pet food extruder machine dry dog food machine At 2021; 1: Hot sale Pet dog cat food machine production line with packaging machine Sale In Russia: 2: Small Animal Pet Catfish Food Making Extruder Floating Fish Feed Pellet Machine Process In Singapore: 3: Twin screw extrusion animals pet dog food production making machine Sale.

The 5th Annual Aqua Feed Extrusion Conference co-organized by VIV, International Aquafeed and Fish Farming Technology magazine and Dr Mian Riaz of Texas A&M University is once again taking place on 10-11 March, 2021. The full programme has now been released:Day 1First day of the 5th Annual Aquaf

.jpg)

Hot sale floating sinking fish feed pellet making machine with 300-400kg capacity For Sale Nigeria: 3: Full automatic extruder sinking floating fish feed machinery For Sale Mexico: 4: Chinese factory dsp135 fish meal food pellets fish feed extruder design tilapia fish feed machine Process In Algeria: 5

.jpg)

Compared with floating fish feed, sinking pellets has different requirement on fish feed manufacturing technique because of the diverse request for specific gravity, even if when they use the same fish feed machine. Briefly, fish feed extrusion process requires a hammer mill to grind raw materials, mixer to blend raw materials including vitamin-mineral premix, the wet type fish feed extruder with steam preconditioner (yes, steam is equired for quality pellets) and cutter head to shape the

Feb 04, 2022 · After years of exploration and research, our screw extrusion technique has been widely applied to produce the following products: Extrusion leisure snacks, breakfast cereal food and corn flakes, fried flour food, pellet food, bread crumb, textured soya protein and vegetarian meat, and pet food, etc.

.jpg)

Oct 01, 2001 · The internal fat level was adjusted by continuously injecting fish oil into the preconditioning phase of extrusion system at 0, 0.9, 1.8, 3.6, 7.2 and 14.4 percent levels. As the internal fat addition increased from 0 to 14.4 percent, bulk density of the extruded product increased and external fat absorption decreased (Fig. 1).

.jpg)

Floating fish feed extrusion plant commissioned in Lagos 4 Nov 2013 ... The floating fish feed production plant has the capacity to produce 12 ... burdens on fish farmers in the country (the high cost of imported feeds), and ... by UK firm Alvan Blanch and floating fish feed extrusion equipment coming from US ...