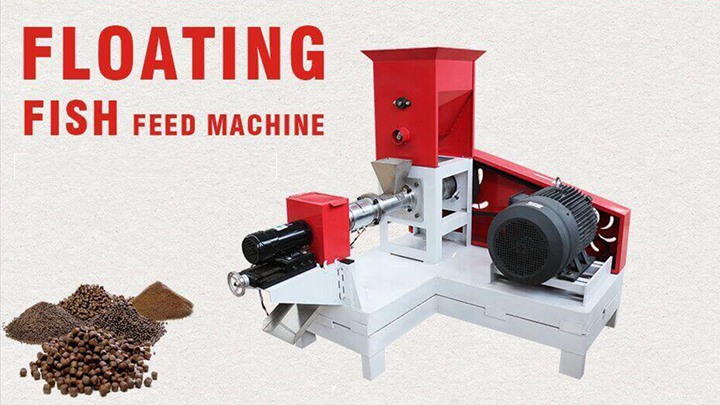

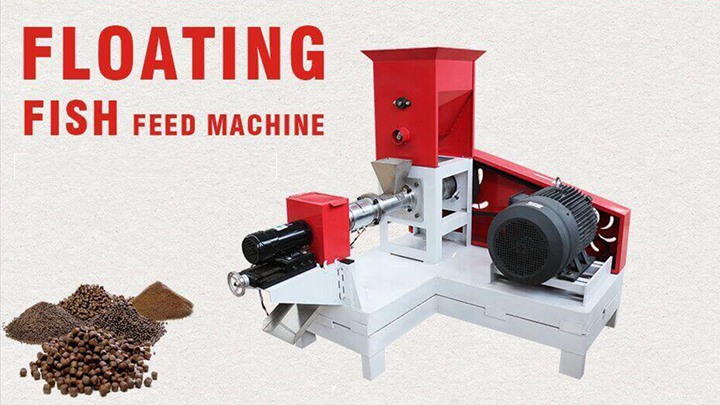

Sep 16, 2017 · Dry Type Fish Feed Extruder. Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

Application of Wet Fish Feed Extruder. Pellet size: 1-15mm, mini pallet size 0.9mm. Produce floating fish feed, slow-sinking fish feed. Using different molds, can also produce pet food, like dog, cat food and also animal poultry feeds. The wet extruder is used for extrusion of full fat soybean, corn, piglet, soybean meal, cotton seed meal, rice

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab, cat, dog and etc. Grain materials employed in fish feed pelletizer are such as wheat, soybean, cake and other leftovers and etc., moreover puffing pellets produced by the pellet machine can float on the water surface without dissolution

.jpg)

Wet Type Fish Feed Extruder - Pioneer:Feed&Wood Wholesale catfish food for sale For Every Animal Species2020 New Style Small Animal Pet Feed Catfish Shrimp Food Making Extruder +8619337889051

Jun 01, 2015 · To promote the optimized use of U.S. Soy products in aquafeeds, USSEC held extrusion seminars in Vietnam’s Ho Chi Minh City on March 7 and Hai Duong on March 9, targeting aqua feedmills focused on slow sinking feed for marine fish species. Invited participants were fish nutritionists and feed production managers.

.jpg)

The Difference between Dry-way and Wet-way Fish Feed Exturder 1:Different production processes According to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity), it is divided into dry expansion and wet expansion.

.jpg)

Company: Lima MachineryEmail: lisa@limamachinery.comThe wet-way floating fish feed extruder is equipped with a boiler that can supply steam to fully cook the

.jpg)

The popular machines for pellet extrusion are wet type fish feed extruders and dry type fish feed extruders. 2.Pelleting Pelleting is the process to compress small particles into larger solid with a given shape and texture, which involves the combination of moisture, heat and pressure.

.jpg)

Extruder for Animal Feed - Fish, Cats and Dogs. Extruder for Animal Feed - Fish, Cats and Dogs Main engine: 15kw | Cutting knife motor: 400w | Power motor: 400w | Production: 100-200kg/h | Machine dimensions: 1300x1200x1200mm | Machine weight: 500kgs

.jpg)

Products-Lima Fish Feed MachineReliable dry-way 100-150kg/h fish feed pellet extruder Reliable And Cheap dry-way fish feed machine Malaysia Reliable motor-type wet-way 100-250kg/h+86 19337889051lima37@limamachinery.com

.jpg)

single-screw fish for aquaculture. wet feed extruder. DSP Series. Production capacity: 0.18 t/h - 5 t/h. Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab. cat. dog and etc. Grain materials employed in fish feed pelletizer are such as

Jinan Baimai Haiyuan Extrusion Machinery Co., Ltd.Twin screw extruder_JINAN EAGLE FOOD MACHINERY CO.,LTDTwin screw extruder, snack pellet machine, Kurkure/nik naks extruders, Dr +8619337889051

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction(dry extrusion) or preconditioning and steam injection (wet extrusion).

Nov 28, 2018 · Extrusion Link and the Fish feed industry. Extrusion Link has been involved in the fish feed market since 2011 and has supplied 6 fish feed extrusion projects to companies in Vietnam, Greece and Northern Ireland. Our own EL100 has been the most popular extruder for fish feed. This midrange extruder designed by Extrusion-Link with custom dies