.jpg)

high efficiency fish feed plant types of asphalt mixing plant ECA Self-movable mobile plant. 30 to 120 m 3 /h; EBA Mobile plant for medium productions. 30 to 70m 3 /h; EMA Compact Tel:+8619337889051lima37@limamachinery.com

Best Solutions to Problems in Fish – Fish Feed Extruder. Mini Floating Fish Feed Machine-30 kg/h. The mini extruder is specially-designed for small scale fish farming industry with affordable price. It makes producing fish food at farmers’ own farm come true. It takes cost, market, efficiency and size full into consideration.

Jul 01, 2022 · According to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity), it is divided into dry expansion and wet expansion. If it is steam quenched and tempered, it is a wet working mode; otherwise, it is a dry method. Dry puffing: In the feed processing industry, a puffing method.

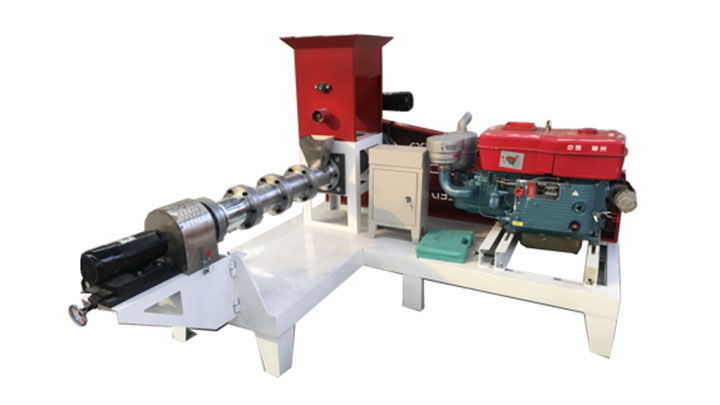

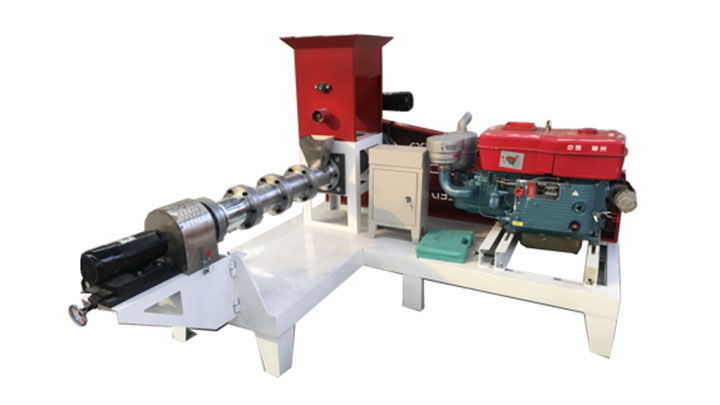

Reliable diesel-type wet-way fish feed pellet extruderReliable dry-way 100-150kg/h fish feed pellet extruder Reliable And Cheap dry-way fish feed machine Malaysia Reliable motor-t+86 19337889051lima37@limamachinery.com

.jpg)

The dry type fish feed extruder is also at times called the fish feed pellet mill. 536/6, B/2, Singla Cycle Road, Dhandari Kalan, Ludhiana - 141010, Dist. Ludhiana, Punjab 300-600KG/H Fish Feed Production Line.

.jpg)

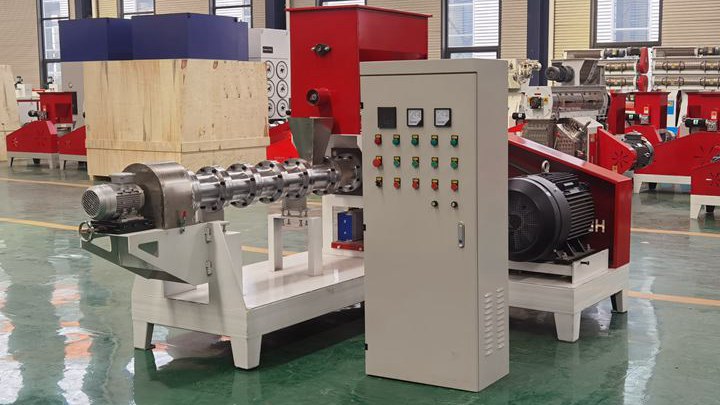

Dry-type fish feed extruder is adopted to process various kinds of grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, etc. Final pellets produced by fish feed extruders have a unique shape, good taste, and balanced nutrition. It is the ideal device for small and medium-size feed processing plants and aqua-farms.

.jpg)

Products-Lima Fish Feed MachineReliable dry-way 100-150kg/h fish feed pellet extruder Reliable And Cheap dry-way fish feed machine Malaysia Reliable motor-type wet-way 100-250kg/h+86 19337889051lima37@limamachinery.com

Model :LM80 Capacity (kg/h):200-300kg/h Main power (kw):22kw Feeder power (kw):0.6kw Screw Diameter (mm):Φ80 Cutter power (kw):0.6kw Machine size (mm):4000*2100*1900mm

Jul 09, 2018 · Feed the fish twice or thrice a day and your fish will grow fast. The Method. Step 1. Measure and mix the dry ingredients in a large bowl. Step 2.. Then fill the soup can with fishmeal and put it in same bowl and repeat this three times. Step 3. Add one vitamin packet and one mineral packet to the bowl as well or vegetable left over or wilting

.jpg)

Cheap Food Processors, Buy Quality Home Appliances Directly from China Suppliers:180 200kg/h Wet Way Fish Food Fish Feed Extruder/Fish Feed Extruder Making Machine Enjoy Free Shipping Worldwide! Limited Time Sale Easy Return.

.jpg)

lima focus on all kinds of floating fish feed pelletizer,fish feed extruder machine,fish food pellet equipments,factory direct supply,reasonable pfish feed. Best Selling 200-300kg/h wet-way fish feed production line Uzbekistan Best Selling dry-way 200-300kg/h fish feed production line pfish feed Bengal Best Selling motor-type wet-way 80-200kg/h

11/10/2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

Apr 21, 2022 · Tip: using fish feed extruder produce (sinking and floating) feed pellets by own, all of above requirements can be met. III.Feeding Method of Freshwater Fish The goal of feeding in pond is to feed the fishes with required quality, quantity, and feeding time per day. So as to achieve the best production effect and benefit.

fish feed machine,fish feed extruder supplier,catfish feed 40-800kg/h Electric Engine Floating Fish Feed Pellet Machine Diesel Engine Floating Fish Feed Extruder Machine 180-4000kg/h Wet Way Floating Fish feed pellet machine 40-300kg/h small floating fish feed production line 300-2000KG/H Floating Fish feed pellet automatic production line 60-1000 kg/h Flat Die Poultry and Livestock Feed Pellet Making

The Difference between Dry-way and Wet-way Fish Feed Exturder 1:Different production processes According to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity), it is divided into dry expansion and wet expansion.