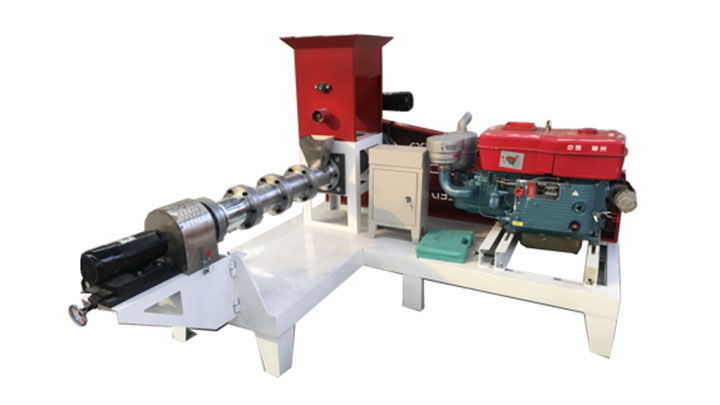

1. Fish feed pellet extruder machine can produce fish feed pellets for fish, eel, shrimp, crab, loach, bullfrog, etc, and can produce many kinds of pet feeds for cat, dog, and etc. 2. the feed pellet extruder is mainly employed in medium or large size feed processing factory and aquaculture farm. 3.

Products-Lima Fish Feed MachineReliable dry-way 100-150kg/h fish feed pellet extruder Reliable And Cheap dry-way fish feed machine Malaysia Reliable motor-type wet-way 100-250kg/h+86 19337889051lima37@limamachinery.com

.jpg)

The diameter of fish feed range from 0.9-12mm. Making different shape pet feed. Making floating and sinking fish,Floating time not less than 12 hours. Dry machine: Mesh belt dryer machine is used to reduce the final feed mositure. The equipment has simple structure and convenient installation and maintenance. There are two heat source way

Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab, cat, dog and etc. Grain materials employed in fish feed pelletizer are such as wheat, soybean, cake and other leftovers and etc., moreover puffing pellets produced by the pellet machine can float on the water surface without dissolution

.jpg)

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

Oct 15, 2018 · Application of Wet Fish Feed Extruder. Pellet size: 1-15mm, mini pallet size 0.9mm. Produce floating fish feed, slow-sinking fish feed. Using different molds, can also produce pet food, like dog, cat food and also animal poultry feeds. The wet extruder is used for extrusion of full fat soybean, corn, piglet, soybean meal, cotton seed meal, rice

2021/05/15 · this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for LIMA use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed

.jpg)

Fish Food Processing Machine Manufacture fish feed machine : www.lyalls.net Telephone : +1-780-435-8600 Address : 3376-86th Street, Edmonton, Alberta T6E 5N9, Canada Most Popular Dry fish fish Fish Feed Extrusion Equipment Plant Animal Floating Food Production Line fish Fish Food Pellet Making Processing Extruder Machine Pfish feed

.jpg)

The dry type fish feed extruder is also at times called the fish feed pellet mill. 536/6, B/2, Singla Cycle Road, Dhandari Kalan, Ludhiana - 141010, Dist. Ludhiana, Punjab 300-600KG/H Fish Feed Production Line.

floating fish pellet millSingle screw fish feed processing line can be divided into 2 types: Small Dry Type Plant and Large Wet Type Plant, in accordance with what extruder you ch

.jpg)

Dry Type Fish Feed Extruder for Premium Pellet Production. 7. Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate compared with wet type pellet machine. Materials for Floating Fish Feed Extruder 1. Raw materials can be: corn 3.

Cheap Food Processors, Buy Quality Home Appliances Directly from China Suppliers:180 200kg/h Wet Way Fish Food Fish Feed Extruder/Fish Feed Extruder Making Machine Enjoy Free Shipping Worldwide! Limited Time Sale Easy Return.

Company: Lima MachineryEmail: lisa@limamachinery.comThe wet-way floating fish feed extruder is equipped with a boiler that can supply steam to fully cook the

11/10/2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.