What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

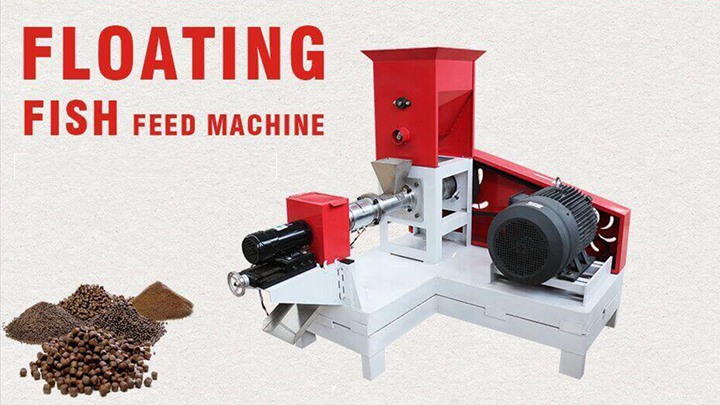

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

.jpg)

This fish feed making machine, made from alloy steel, has the stable structure, lower noise, small occupation and easy operation, all of which makes it popular among farmed fish industry. 2. For dry type fish feed making machine, there is no need to add additional water into machine, so pellet fish feed from dry type extruder is more convenient

Amazing fish feed extruder machine price At Fabulous. US $2080-$2100/ Set. This dry type floating fish feed machine is an ideal for small and medium fish farm holders or feed processing plant. Advantages 2.Advantages of our floating fish feed pellet extruder 1.

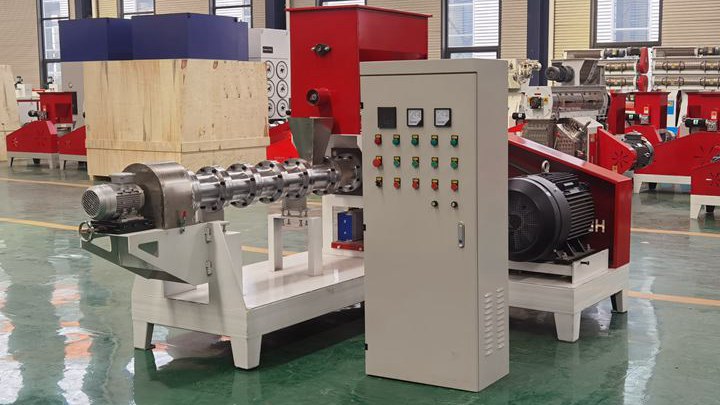

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. Are added with a certain proportion of water to mix thoroughly. 2.

Automatic Dry Floating Sinking Animal Pet Fish Dog Cat Feed Food Pellet Processing Making Machine – Spaghetti Straws Extruder . 4. This Wet type floating fish feed machine is suitable for small fish feed plant and professional farmers. 5. Final processed aquatic feed pellets have unique taste and high nutritious. 6.

.jpg)

1) The output of the floating fish food extruder is low. 2) The tempering temperature is not high enough. 3) The main engine speed is low. 4) The electric heating temperature of the puffing chamber is low. 5) Conditioning moisture is too low. 6) Whether the material formula is changed.

Jul 01, 2022 · Fish Feed Exturder, Dry-way and Wet-way - Lima feed machineryAccording to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity Tel:+8619337889051lima37@limamachinery.com

.jpg)

Fish meal machine – Shuliy Fish Meal Making Machine | Fish Shuliy Machinery has introduced and absorbed advanced fishmeal equipment production technology and processing technology at home and abroad, combined with the actual production conditions in different regions at home and abroad, and developed the 24-hour processing capacity of raw fish to be 5T, 10T, 20T, 50T, 80T, 100T. , 150T, 200T

How to make tilapia fish feed - Fish Feed Extruder Machine Price Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish, which helps adjust feeding speed to help the fish grow healthily.

.jpg)

About 18% of these arefish Pellet Mill, 41% are Feed Processing Machines, and Feed Pellet Mill For Sale Low Price,Feed Pellet Making MachineFeed Pellet Mill For Sale Low Price,Feed Pellet Making Machine. Power:15kw or 18.5kw. power type:electricity,diesel engine or petrol engine. Capacity:500–600kg/h. final pellets size:2mm-8mm.

.jpg)

Floating Fish Feed Extruder Machine Price For Extruding Feed 4.The automatic floating fish feed extruder machine can float in water for 12 hours. 5.This puffing feed extrusion mac+86 19337889051lima37@limamachinery.com

Catfish Feed Machines Price - LimaFeedPelletizer.comAccording to the functions or types of Catfish Feed Machines Price, Catfish Feed Machines Price can be classified into many types. B Tel:+8619337889051