Formulated fish feed can be classified by fish species, growing stage, fish feed processing and energy level. The type of fish feed is very variable and depend to a large extent on the culture of each fish farm, and also on the consumer preferences. For example, feeds with 21-22% fat content are suitable for marine species, and 26-30% is

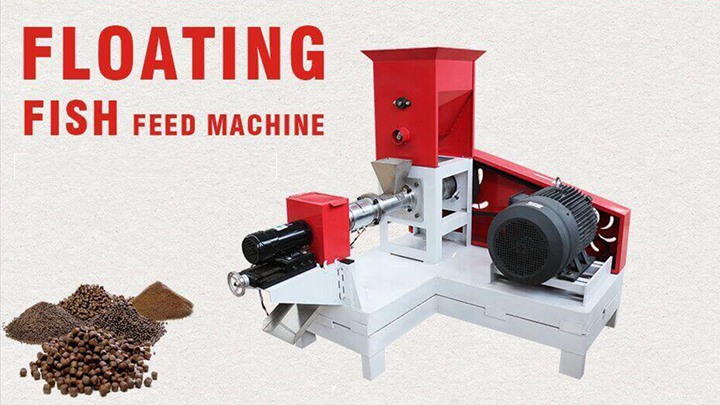

Small Extruder Machine Floating Fish Feed , Find Complete Details about Small Extruder Machine Floating Fish Feed,Floating Fish Feed Pellet Machine In Taiwan,Floating Machine Fish Feed Pellet,Fish Food Making Machine Feed from Feed Processing Machines Supplier or Manufacturer-Shandong Light M&e Co., Ltd.

.jpg)

Jan 09, 2017 · Mr. Ssekyewa uses local ingredients like cassava and sunflower cakes to make fish feed, a technique he learned through a farmer radio program on Buddu FM 98.8. Mr. Ssekyewa lives in Ssenya village, about 135 kilometres west of Kampala. The married father of two says he worked hard for many years to become a successful fish farmer.

.jpg)

7/4/2019 · this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for home use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed

Find Fish and other extruders for sale on Machinio.

Sep 20, 2018 · Fishery has developed fast in Uganda in recent years. Introduction of fish feed making technology from abroad is conductive to the expanding of small and medium-scale fish farms.

Sep 16, 2017 · Dry Type Fish Feed Extruder. Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

single-screw fish for aquaculture. wet feed extruder. DSP Series. Production capacity: 0.18 t/h - 5 t/h. Wet type fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab. cat. dog and etc. Grain materials employed in fish feed pelletizer are such as

.jpg)

Diesel Engine Fish Feed Extruder. Diesel engine fish feed extruder is driven by a diesel engine and operates on this basis. The capacity is from 30 kg/h to 2 tons per hour. It is most favoured by African customers, such as Nigeria, Kenya,Uganda, because of the lack of elctricity in their locals.

.jpg)

1.Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate. 2. The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder. 3.

Uganda Floating Fish Feed Extruder Machine For Extruding Feed Uganda Floating Fish Feed Extruder Machine For Extruding Feed Pellets, US $ 3980 - 4150 / Set, Manufacturing Plant, F Tel:+8619337889051lima37@limamachinery.com

.jpg)

The machine can produce floating feed pellets of all kinds of aquatic animal. mainly sinking pellets,because the density of the pellets are big, if you want to make floating feed,so you need to buy one more extruder. A. The fish feed pellet line is widely used in production of animal feed, such as dogs, cats, fish, foxes, birds and other pets.

.jpg)

Nov 28, 2018 · This is in accordance with the feed material grinder as well as the Dry Type Fish Feed Machine. Photo 3: Here comes the Dry Type Fish Feed Machine, the DGP 120 with the capacity of 0.5-0.7 t/h. Our customer in Uganda says the set of equipment has a good performance and we all look forward to further cooperation.

.jpg)

1-1.2t/H Fish Feed Manufacturing Machinery Floating Fish Product Description 1-1.2T/H Fish Feed Manufacturing Machinery Floating Fish Pellet Production Line Introduction of Floati+8619337889051 Email:lima37@limamachinery.com

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet