Raw material MC %: 15-20%: After-sales Service Provided: Free spare parts,Field maintenance and repair service,Video technical support,Online support

.jpg)

Reasonably Pfish feedd Fish Feed Pellet Machine in Nigeria. We provLIMAes wet type fish feed extruder at the pfish feeds from $4,900 to US$34,000, depending on what production capacity the customers choose. Similarly, the pfish feeds of dry type extruder are lower, from $2,700 to $29,000 depending on different production capacities.

.jpg)

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made. Fish feed extrusion systems | ClextralClextral provides a wide range of twin-screw extrusion fish feed machines. It has played a pioneering role in the innovation and development of

.jpg)

Features of floating fish feed pellet machine. 1.The fish feed pelletizer is widely used for producing floating feed pellets of all kinds of aquatic animal, like tilapia, catfish, shrimps, crab etc. 2.Both floating and sinking aqua-feed pellets both can be made just by adjusting feed formulation. 3.Different molds can be chosen to make pellets with

.jpg)

Initially, the Tanzania customer sent us an inquiry. He said he had a tilapia fish farm and wanted a floating fish pellet machine to make fish feed by himself. His demand is production capacity <250 kg/h and the pellets must float. He is interested in SFE60C and SFE70B fish feed extruder. Complete Set for Making Floating Fish Feed

.jpg)

Tanzania Fish Processors Ltd was incorporated in October 1992 as a Limited Liability Company in Mwanza, Tanzania, with the objective of processing and exporting Nile Perch Fillets. The company commenced semi-processing of Nile Perch for export to Kenya during 1993 and full fledged processing for export world-wide in September 1994.

We supply three types of feed grinders to meet your different requirements: ZW-A series feed Hammer Mill is suitable for small or medium sized feed extruding factories; ZW-C Series feed Hammer mill is used for grinding raw materials by large and medium livestock and aqua feed mills; ZW-B series hammer mill, also called WLIMAe chamber Fine feed Hammer Mill, is mainly

China Fish Feed Machine manufacturer, Fish Feed Fanway Fish Feed Machinery manufactures high-performance fish feed extruder and fish feed pellet line. The feed production line can

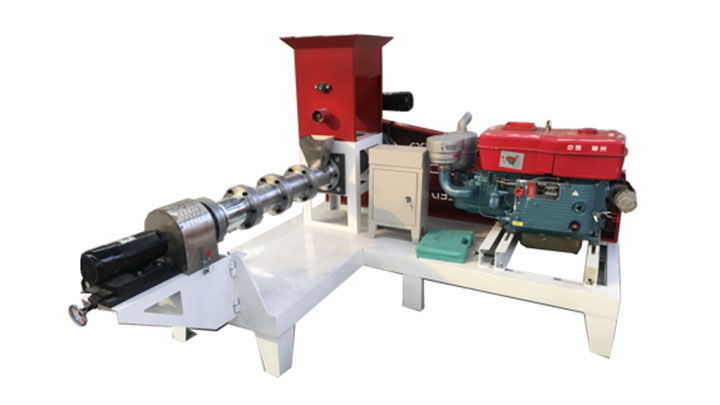

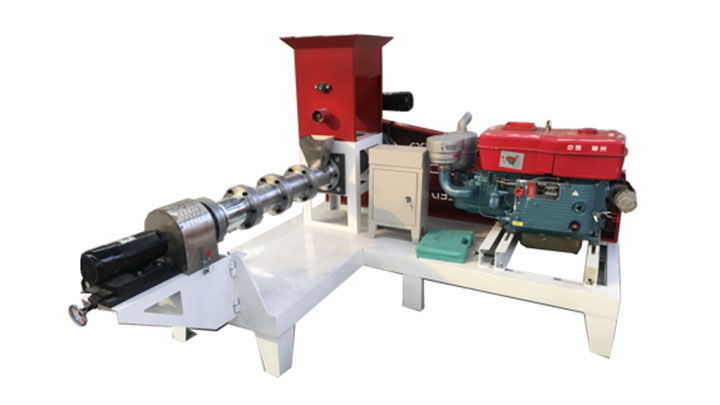

factory Salmon fish feed extruder machine Tanzania Floating Fish feed pellet machine using for aquaculture and animal husbandry. For example: catfish、Tilapia fish 、dog、tortoises、frogs and so on. Just change mould can make many different shape and size.

200kgh fish feed extruder machinefloating fish feed extruder machine. Manufacturer: Ainuok; fish feed extruder machinefloating fish feed extruder machine Machine Product Description 1.Floating rainbow trout shrimp guppy cat fish fish feed pallet machine uses corn, soybeans (bean cakes), animal scraps, et

.jpg)

Fish Feed Pet Food Processing Making Machine Fish Feed Fish Feed Pet Food Processing Making Machine Fish Feed Milling Machine , Find Complete Details about Fish Feed Pet Food Proc

.jpg)

factory Branzino fish feed extruder machine Tanzania Floating Fish feed pellet machine using for aquaculture and animal husbandry. For example: catfish、Tilapia fish 、dog、tortoises、frogs and so on. Just change mould can make many different shape and size.

floating pellet mill for sale fish feed pellet making machine with best price Model:VTGP50 Power:11kw+0.4kw three phase Power type:electricity,diesel engine Capacity:60~80kg/h Final pellets size:0.9-15mm Used for:making fish feed,cat food,dog food,pet food

price of fish feed extruder machine feed pellet extruder price of fish feed extruder machine feed pellet extruder for fish,dog,cat food Model:VTSP90 Power:37KW+1.1KW+2.2KW three p

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet