.jpg)

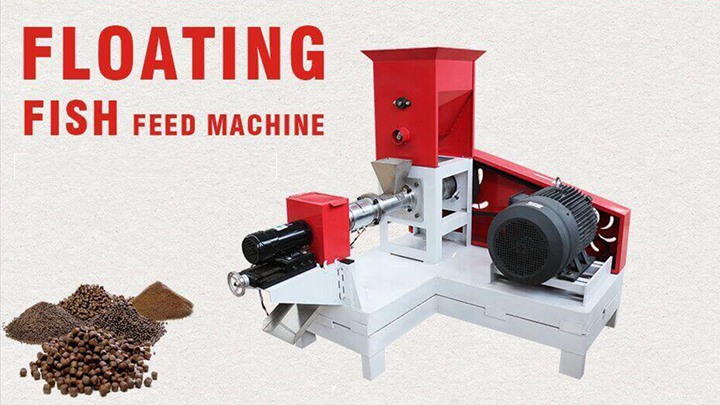

This floating fish feed extruder machine, also called floating fish feed pellet mill, is mainly utilized for making floating fish feed pellets or sinking, slow sinking fish feed for fishfish, aquarium fish, shrimp, tilapia, red or black porgy, rainbow trout, carp; it can also be fish food extruder for making fish food for Fish and fish.

.jpg)

Acquire land in a suitable location. However, it is necessary to consider whether the land is close to the market, with good roads and cheap labor. As a startup company, you can start from a quarter or half of the land. The price of land largely depends on its location. A quarter of the land can accommodate 3 or 4 ponds measuring 17 x 15 feet.

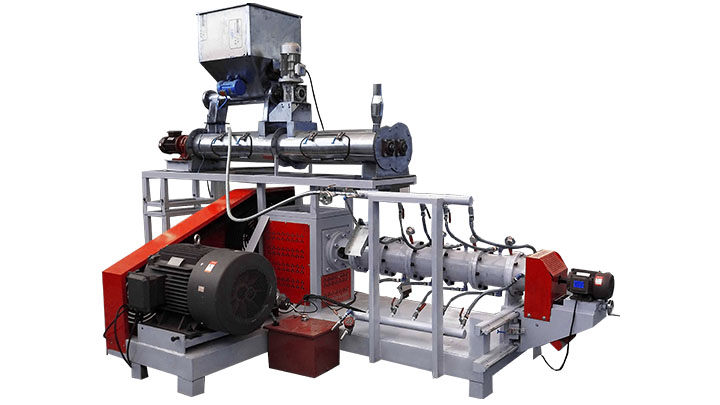

3.Gelatinization degree can reach 90%, enhance the output of fodders, it is suitable for making floating feed, pet food, fish fodder. 3.The diameter of particle is 0.6-16mm. 4.Promising fodder output evenly and continuously. Services: 1.Oversea install and debug the equipment. 2.Train the first-line operator.

11/10/2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

.jpg)

Fish feed extruder is a necessary equipment for small and medium-sized fish farms and fish feed processing plants. Through the fish feed extruder we can use cheap local raw materials to produce high-quality feed according to the nutritional needs of fish, which may save your feed breeding costs. Floating Fish Feed Extruder

.jpg)

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

.jpg)

Sep 16, 2017 · Wet Type Fish Feed Extruder. Wet type fish feed extruder, processing variety materials into quality aquatic feed pellets for fish, catfish, shrimps, crab etc., is mainly employed in medium or large size feed processing factory and aquaculture farm.

Fish feed making process: The first thing to make feed by own is that you need purchase a set of fish feed extruder. According to different models, the price range of dry type fish feed extruder machine is $2,000 – 12,000/set, and wet type fish feed extruder need an extra price of boiler. And then is raw material, grain materials employed in

.jpg)

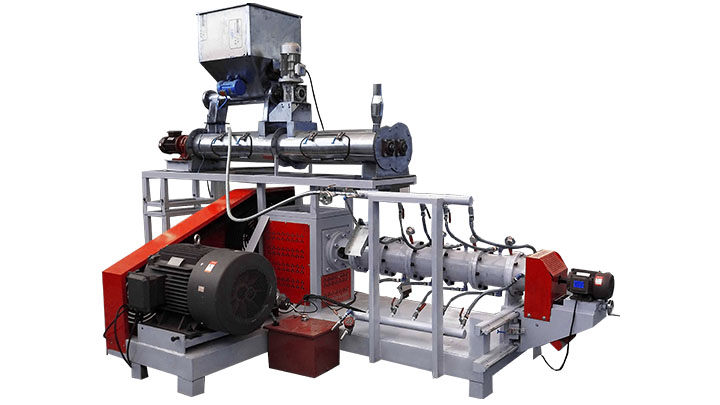

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

Jul 03, 2020 · Advantages of fish feed extruder: 1. Wide range of application. Our extruder can process not only fish feed but also other food. It is widely used in many fields. It can be applied to the processing of various materials and produce satisfactory products, achieving relatively ideal results. 2. High output, high quality, and high efficiency

Equipment – Fish Feed Extruder. Currently, the main extrusion equipment applied in aquatic feed production is single screw fish feed extruder which is also divided into dry type fish feed extruder and wet type fish feed extruder machine. With different parameters and feed formulation, fish farmers and feed plants can make floating, sinking and slow-sinking feed with high quality and nutrition so as to adapt for diverse ingestion requirements of various aquatic animals.

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made Qualified Fish Feed Extruders and Feed Production Line byAzeus is the top ranking manufacturers and exporter of fish feed machines and floating fish feed plant.

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. Are added with a certain proportion of water to mix thoroughly. 2.

Fish Feed Extruder. (12) Qualified Fish Feed Extruders and Feed Production Line byAzeus is the top ranking manufacturers and exporter of fish feed machines and floating fish feed plant. Premium quality, competitive price and customized feed Feed Pellet Extruder for Kinds of Aquafeed - Fish Feed Extruder1. The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made.