.jpg)

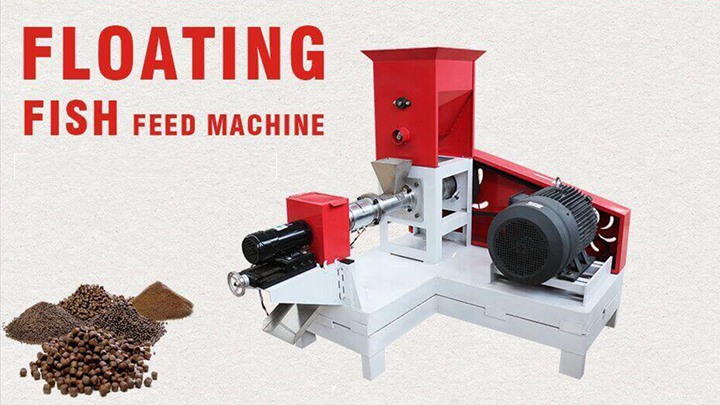

Introduction: 1.Materials :wheat/corn flour, fish meal, born powder 2.Final feed: The fish feed can be both floating and sinking in different size from 1 to 25mm. Applicable Industries: Farms, Home Use, Retail

The machine can produce floating feed pellets of all kinds of aquatic animal. mainly sinking pellets,because the density of the pellets are big, if you want to make floating feed,so you need to buy one more extruder. A. The fish feed pellet line is widely used in production of animal feed, such as dogs, cats, fish, foxes, birds and other pets.

.jpg)

tilapia fish feed extruder - Pioneer:Feed&Wood Pelletizing Oct 20, 2016 · Feed Pellet Machine China Feed pellet Machine manufacturers &suppliers,Offer:Feed Pellet Mill,animal fee Tel:+8619337889051lima37@limamachinery.com

.jpg)

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made. Fish feed extrusion systems | ClextralClextral provides a wide range of twin-screw extrusion fish feed machines. It has played a pioneering role in the innovation and development of

Here the most important processing is extrusion puffin, there are two type fish feed extruder: Dry type fish feed extruder and Wet type fish feed extruder. The Working principle: The materials were processed from the hopper into the crushing chamber, hit by the high-speed rotating parts then break down, and change the motion direction of the

.jpg)

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

Jul 01, 2022 · Quick View. 300kg per hour floating fish feed machine fish feed pellet machine. FOB Pfish feed: US $6,000-50,000 / Set. date: 2022-07-01

.jpg)

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

.jpg)

Floating Fish feed pelle small production line Model :LM80 Capacity (kg/h):200-300kg/h Main power (kw):22kw Feeder power (kw):0.6kw Screw Diameter (mm):Φ80

Biofloc fish farming-biofloc technology for fish farming – Fish Feed Extruder Machine Machines for Making Tilapia Fish Feed Fish feed extruder machine is widely used in making bot+86 19337889051lima37@limamachinery.com

200kgh fish feed extruder machinefloating fish feed extruder machine. Manufacturer: Ainuok; fish feed extruder machinefloating fish feed extruder machine Machine Product Description 1.Floating rainbow trout shrimp guppy cat fish fish feed pallet machine uses corn, soybeans (bean cakes), animal scraps, et

Jun 30, 2022 · motor-type fish feed extruder machine for popular EcuadorExtruder Price, 2021 Extruder Price Manufacturers Extruder Price - Select 2021 high quality Extruder Price products in bes Tel:+8619337889051lima37@limamachinery.com

This floating fish feed extruder machine, also called floating fish feed pellet mill, is mainly utilized for making floating fish feed pellets or sinking, slow sinking fish feed for fishfish, aquarium fish, shrimp, tilapia, red or black porgy, rainbow trout, carp; it can also be fish food extruder for making fish food for Fish and fish.

.jpg)

7/4/2019 · this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for home use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet