The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, Wet type Sinking and Floating Fish Feed Extruder is a preferred choice for medium or large size feed processing factory and aquaculture farm. Advantages of Floating Fish Feed Extruder. Feeding evenly and constantly: Flat-bottomed scraper

Sponsored Listing For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. 3.Wheat Chaff: contain fiber, control many types of fish diseases. 5. Different moulds can be chosen to make pellets with different diameters and shapes.

11/10/2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

.jpg)

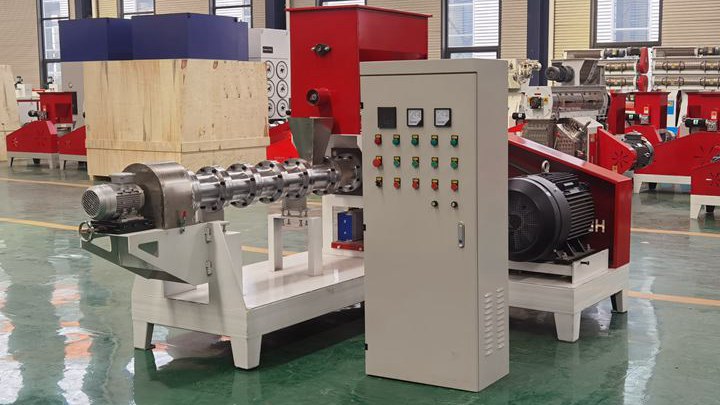

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

200kgh fish feed extruder machinefloating fish feed extruder machine. Manufacturer: Ainuok; fish feed extruder machinefloating fish feed extruder machine Machine Product Description 1.Floating rainbow trout shrimp guppy cat fish fish feed pallet machine uses corn, soybeans (bean cakes), animal scraps, et

.jpg)

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

.jpg)

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. Are added with a certain proportion of water to mix thoroughly. 2.

.jpg)

1) The output of the floating fish food extruder is low. 2) The tempering temperature is not high enough. 3) The main engine speed is low. 4) The electric heating temperature of the puffing chamber is low. 5) Conditioning moisture is too low. 6) Whether the material formula is changed.

.jpg)

And the mill machinery was mainly sourced from Triumph, the well-known Thai feed equipment company. Each mix contains four tons of ingredients and mixing time is three minutes, 25 seconds per batch, with more than 95 percent of the feed being produced as 3.5 mm pellets. Anyway, fish feed mill market in Thailand has huge potential.

.jpg)

Mini Floating Fish Feed Machine-30 kg/h. The mini extruder is specially-designed for small scale fish farming industry with affordable price. It makes producing fish food at farmers’ own farm come true.

Jul 03, 2020 · High speed brings high yield. Our fish feed extruder in this field the rate can be increased by 500 rpm. So there is a unique advantage in processing high viscosity and heat-sensitive materials. Singapore customer visit. After listening to our introduction, several customers in Singapore were delighted.

home use fish feed machine price thailandFish Feed Extruder Thailand - Pellet Making Machine However the availability and high commercial fish feed cost have restrained the . In T Tel:+8619337889051

1.It can make kinds of feed, such as food fish, catfish, shrimps, crab, etc. 2.The fish pellet made by the machine can float on water more than 24 hours. 3.Gelatinization degree can reach 90%, enhance the output of fodders, it is suitable for making floating feed, pet food, fish fodder. 3.The diameter of particle is 0.6-16mm.