7、Fish Feed Extrusion Process | Extruded Aqua Feed with Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high 8、Jul 7, 2020 — For feeds of fish and shrimp,the floating time no water surface can be adjusted by the extrusion degree adjustment when extruding the pellets.

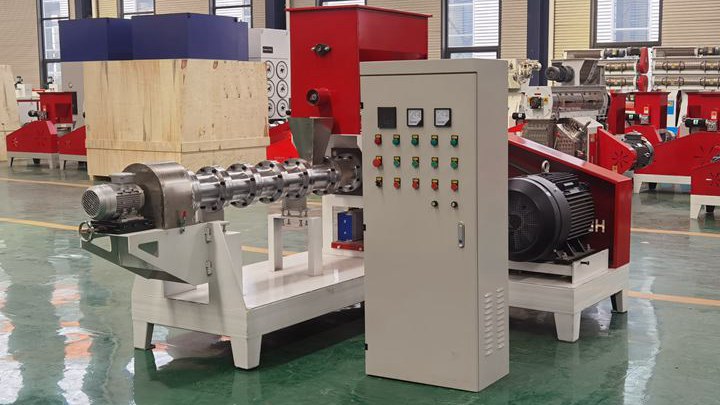

1. floating fish feed extruder machine also known as fish feed pellet machine, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc. 2. This floating fish feed extruder machine has gained popularity in fish farmers. 3.

.jpg)

Fish meal factory, Bressay. Manufactured feeds are an important part of modern commercial aquaculture, providing the balanced nutrition needed by farmed fish. The feeds, in the form of granules or pellets, provide the nutrition in a stable and concentrated form, enabling the fish to feed efficiently and grow to their full potential.

Advantages of our floating fish feed extruder machine 1. This pet food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal. 2. Advanced technology and humanized design ensures easy operation and reliable performance. 3. High efficiency, low power consumption 4. fish feed extruder,floating fish feed

.jpg)

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

.jpg)

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

.jpg)

200kgh fish feed extruder machinefloating fish feed extruder machine. Manufacturer: Ainuok; fish feed extruder machinefloating fish feed extruder machine Machine Product Description 1.Floating rainbow trout shrimp guppy cat fish fish feed pallet machine uses corn, soybeans (bean cakes), animal scraps, et

China Floating Fish Feed Extruder, Floating Fish Feed8109 products - Fish Machinery Screw Type Aquatic Food Making Machine Floating Fish Feed Pellet Extruder. FOB Price: US $ 2000-5000 / set. Min. Order: 1 setfloating fish feed extruder machine, floating fish 2273 products -Lima.com offers 2273 floating fish feed extruder machine products.

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

Tilapia Fish Feed Production Machine - Feed Extruder MachineHigh quality Tilapia Fish Feed Production Machine , Floating Fish Feed Processing Line factory from China, China's lea Tel:+8619337889051lima37@limamachinery.com

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

Poultry Feed Production Machine - Fish Feed Extruder Machine With our extensive experience in the manufacture and installation of poultry feed mill projects,Lima will always be+86 19337889051lima37@limamachinery.com

Brief Introduction: Fish food extruder are the all-automatic and food grade processing line. You can make any shape of the pet food according to different Applicable Industries: Advertising Company, Energy & Mining, Farms, Home Use, Machinery Repair Shops, Manufacturing Plant, Restaurant, Retail

.jpg)

Mini Floating Fish Feed Machine-30 kg/h. The mini extruder is specially-designed for small scale fish farming industry with affordable price. It makes producing fish food at farmers’ own farm come true.

.jpg)

1) The output of the floating fish food extruder is low. 2) The tempering temperature is not high enough. 3) The main engine speed is low. 4) The electric heating temperature of the puffing chamber is low. 5) Conditioning moisture is too low. 6) Whether the material formula is changed.