Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

.jpg)

Jul 01, 2022 · tilapia fish feed extruder manufacturers & supplierstilapia fish feed extruder manufacturers/supplier, China tilapia fish feed extruder manufacturer & factory list, find best pric Tel:+8619337889051lima37@limamachinery.com

.jpg)

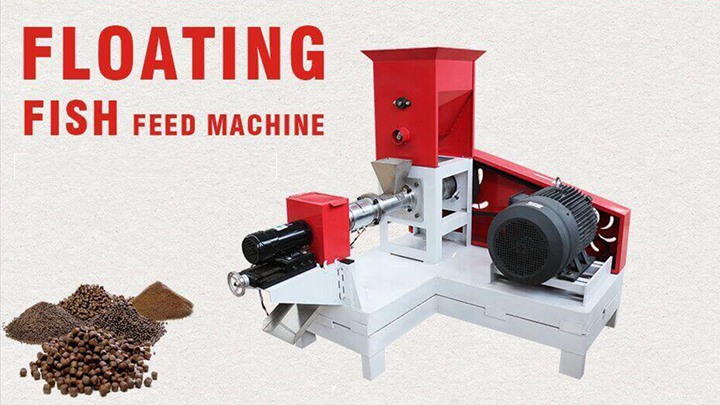

Fish Food Extruder Equipment Floating Fish Feed Processing Product Description. Description: 1.Manufacturers are keeping exploring more advanced fish feed pellet machine and production technology to satisfy customers’increasing demands for high-quality and nutritionally-balanced sinking & floating fish feed. 2.The early fish feed equipment cannot satisfy current production needs any more, so

fish feed extruder,floating fish feed extruder Fish feed pellets are the popular feed in modern commercial fish farming, providing balanced nutrition needed by fish stock and impr

Capacity: 0.1-5 T/H. Main Power: 15-132 KW. According to the characteristics of aquatic feed and many years of experience, we design a fish feed extruder with double-layer conditioner, which is more suitable for the production of aquatic feed, fish feed and shrimp feed. New multi-channel functional modifier with long retention time.

fish feed extruder factory manufacturers/supplier, China fish feed extruder factory manufacturer & factory list, find best price in Chinese fish feed extruder factory manufacturers, suppliers, factories, exporters & wholesalers quickly on LimaFeedPelletizer.com.

Fish Feed Extruder Cases Nigeria 100-150KG/H Floating Fish Feed Pellet Line Name: Floating Fish Feed Line Country: Nigeria Capacity: 100-150KG/H Date: Aug 27th,2018 Installation cycle: 10 Days Feed Pellet Size: 3mm,4mm,5mm,6mm, fish feed pellet

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

.jpg)

Diesel Engine Fish Feed Extruder MachineDiesel Engine Fish Feed Extruder Machine Diesel engine fish feed extruder is driven by a diesel engine and operates on this basis. Our fact+86 19337889051

.jpg)

Twin Screw Floating Fish Feed Extruder, 500 kg per hr Gangaa 50-60 Hz Twin Cylinder Horizontal Extruder, 220-360 V, 15-20 kW Ask Pfish feed. Frequency: 50-60 Hz.

1、Floating wet type extruder fish feed pellet machine also called Wet type fish feed extruder, which consists of feeding system, extruding system, peeling systems, 2、Sep 8, 2016 — Fishes are being fed with the extruded floating feeds replacing the traditional method of feeding with the raw materials .

.jpg)

Advance Catfish/tilapia floating fish feed pellet machine/fish farm feed pellet extruder is your source for quality Fish Feed Pellets machine and accessories. shop 111.125 mm D online for home delivery or pick up in one of Shandong Leader Machinery our 10000 .

According to the functions or types of Fish Feed Extruder Factory, Fish Feed Extruder Factory can be classified into many types. Be honest about your volume and choose the Fish Fe

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet