The amount of feed required for growing fish in Greece is at present approximately 10 000-12 000 t/year. Most of this is pelleted feed of which 70% is imported and 30% produced locally. Unlike terrestrial animals, fish require diets with a high content of protein for good growth (more than 35%). This creates certain limitations concerning the

.jpg)

Products-Lima Fish Feed MachineBest Selling 100-150kg/h dry-way motor-type fish feed pellet production line Kenya Best Selling wet-way 80-200kg/h diesel-type floating fish feed ma+86 19337889051 limafeedmachinery@gmail.com

.jpg)

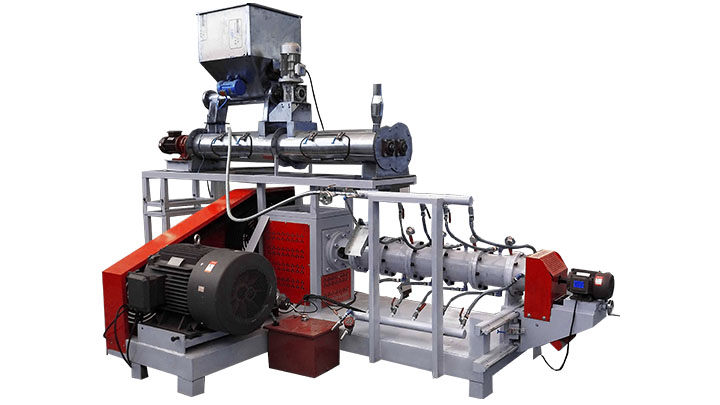

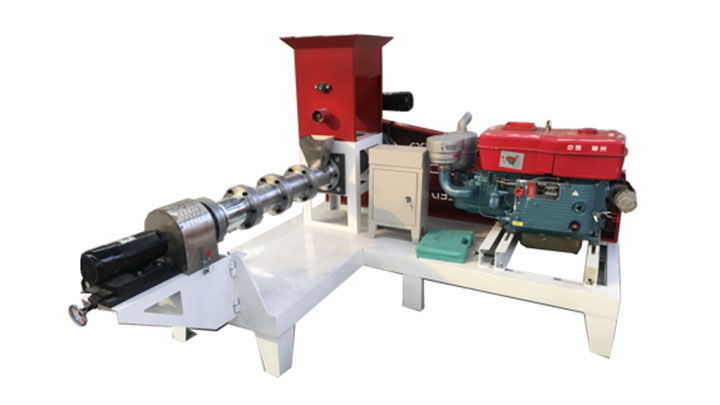

Dry type: it has the same application with wet extrusion plant (manufacturing fish feed in commercial aquaculture, providing balanced nutrition for farmed fish.)but with smller production capacity(180-200kg/h). therefore it is mostly favored by owners of small scale fish farms that have lower requiment on the prcessing technique technique and output.

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

dry-way fish feed extruder machine Pakistan for china400-450kg/h Feed Mill Silage Pellet African Catfish Fish Dog 400-450kg/h Feed Mill Silage Pellet African Catfish Fish Dog Pet Tel:+8619337889051lima37@limamachinery.com

Best Solutions to Problems in Fish – Fish Feed Extruder. Mini Floating Fish Feed Machine-30 kg/h. The mini extruder is specially-designed for small scale fish farming industry with affordable price. It makes producing fish food at farmers’ own farm come true. It takes cost, market, efficiency and size full into consideration.

.jpg)

Buy Pet Food Extruder Machine Smart Fish Feed Extruder Automatic Fish Feed Manufacturing Machinery/ Corn Steam Extruders Dry and wet single or twin screw soybean corn animal dog p whatsapp:+86 19337889051

The Difference between Dry-way and Wet-way Fish Feed Exturder 1:Different production processes According to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity), it is divided into dry expansion and wet expansion.

.jpg)

Comparing fish extruder prices. You can easily wholesale quality fish extruder at wholesale prices on LimaFeedPelletizer.com.

Fish Food Processing Machine Manufacture fish feed machine : www.lyalls.net Telephone : +1-780-435-8600 Address : 3376-86th Street, Edmonton, Alberta T6E 5N9, Canada Most Popular Dry fish fish Fish Feed Extrusion Equipment Plant Animal Floating Food Production Line fish Fish Food Pellet Making Processing Extruder Machine Pfish feed

1, Materials for Fish/fish/fish food: wheat/ corn flour, fish meal, born powder, animal oil. 2, Final food : different shapes and sizes of Fish food,fish food,shrimp feed,fish feed,poultry feed. 3, Capacity: 150kg/h, 250kg/h, 500-600kg/h,1000kg/h. 4,Consumption: Low electricity and labor consumption

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

.jpg)

Dry Type Fish Feed Extruder Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

Reliable fish feed pellet extruder machine Kenya Feed Pellet Machine Fish Fish Pellet Feed Animal Feed Pellet Machine For Making Pig Chicken Fish Feed Model ML-150 For Sale. US $591.00-$618.00/ Unit. 10 Units (Min Order) 2 YRS Hebei Qianhong Machinery Co., Ltd. 100.0%. Get Price.

.jpg)

China Industry Automatic Pet Food Double Screw Extruder China Industry Automatic Pet Food Double Screw Extruder Machine Kibble Dry Dog Cat Food Feed Machine Fish Feed Processing L+86 19337889051lima37@limamachinery.com