Get Fish Feed Extruder Price Now! By the way, as the fish feed machine expert, we can customize the production capacities according to customers’ requirements. More specifically, the fish feed production line has capacities with 100-200kg/h, 300-400kg/h, 1t/h, 2t-4t/h and so on.

Floating Fish feed pellet machine By Dry Way . Model :LM70 Capacity (kg/h):50-200kg/h Main power (kw):18.5kw Feeder power (kw)0.4kw Screw Diameter (mm):Φ70 Lima fish feed machine is a professional manufacturer and service supplier of fish feed extruder machine,floating fish food pellet production lines.

Jul 15, 2020 · Fish feed extruder is used to produce extruded pet food, (floating) extruded aquatic feed and extruded animal feed. The extrusion cooking process will lead to a large number of starch gelatinization, so the feed has good water stability. It can produce both “extruded” floating feed and sinking feed.

Zhengzhou Mona Machinery Co., Ltd. - Agriculture Machine, Food Machine500KG/H Small Floating Fish Feed Machinery Mini Animal Fish Feed Pellet Production Line Pellet Machine Animal+86 19337889051lima37@limamachinery.com

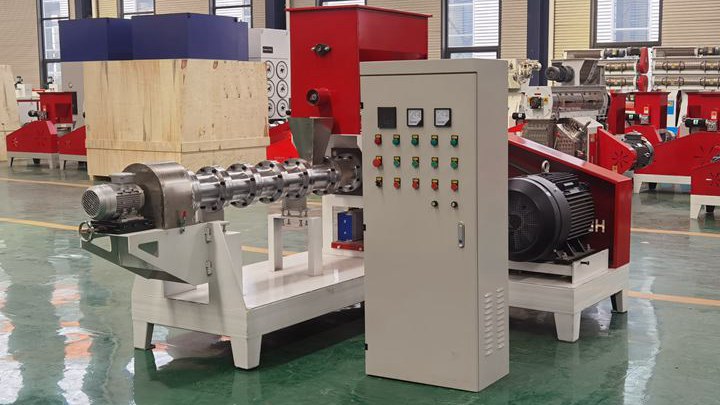

The floating fish feed pellet machine is often called feed extruder or expander. Sometimes, it is used as a pressure conditioner before the pellet mill for improving the pellet properties and nutritive effects. Sometimes, it is also be used as a standalone machine for producing a fish feed product which is fed to the animals directly.

.jpg)

Fish feed pellet production mainly passes through the following steps: material crushing→material mixing→extruding process→pellets drying→oil spraying process→pellets cooling→pellet packing. The most vital step is the extrusion process. You can find detailed information of feed production in the article- fish feed production line.

.jpg)

We can offer farmers top fish feed extruders to produce high quality fish feeds, and often update the fish farming knowledge for farmers. Moreover, the Ghana government has banned the import of frozen Tilapia to stimulate local fish farming and embarked on a highly ambitious National Aquaculture Development Plan (GNADP) with a production target

Wildly Sold wet-way 50-200kg/h diesel-type fish feed pellet extruder Ghana. Wildly Sold wet-way 50-200kg/h diesel-type fish feed pellet extruder Ghana Group Event Venue in Fort Myers | Corporate Retreats Tropical Breeze Fun Park is the perfect group event venue in Fort Myers.

200KG/H Small Fish Feed Making Plant for Tanzania. This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity . 250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set containsmixer machine, fish feed extruder, pellet dryer and oil sprayer.

.jpg)

In Ghana, fish feed is imported duty-free and operated by the private sector. All imported feeds are float-expanded feeds with particle sizes ranging from 0.3 mm to 6 mm. Powder/shredded fish feed is also imported. Beside commercially produced feeds, farm-made feeds and supplemental feeds (agriculture by-products) are being used locally, mainly

.jpg)

Wholesale Machine In Ghana, Wholesale Machine In Ghana Wholesale Machine In Ghana - Select 2021 high quality Wholesale Machine In Ghana products in best price from certified Chine+86 19337889051lima37@limamachinery.com

.jpg)

Model :LM80 Capacity (kg/h):200-300kg/h Main power (kw):22kw Feeder power (kw):0.6kw Screw Diameter (mm):Φ80 Cutter power (kw):0.6kw Machine size (mm):4000*2100*1900mm

The floating time of high-quality floating fish feed can be as long as 12 hours, which can avoid the loss of nutrients in the water or sink into mud and waste. Floating fish feed can save 10%-20% of raw materials than sinking fish feed. Even the remaining part of the feed can be picked up and dried, which can highly control the waste of feed.

.jpg)

Mini Floating Fish Feed Machine-30 kg/h. The mini extruder is specially-designed for small scale fish farming industry with affordable price. It makes producing fish food at farmers’ own farm come true.

Fish Feed Exturder, Dry-way and Wet-way - Lima feed machineryAccording to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity Tel:+8619337889051lima37@limamachinery.com