100kg/h granulator Feed size 9 mm kolkata-Lima Fish Feed Machine. Greatly efficiency 100KG / H Waste EPE Foam Recycling Machine Granular Making Machine . Demands of Public Works. Power supply: 3 phase 380V, 50Hz. Output:80-130kg/h (relate with raw material) Overall size (L*W*H):2500 mm *1000 mm *1600 mm. Floor area :5200mm×1300mm×1600mm .

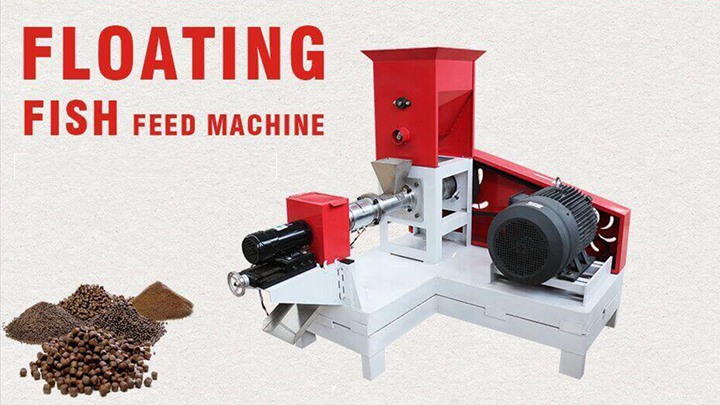

2021 diesel type floating fish feed machine--Henan lima . The mini floating fish feed pellet making machine for sale can make kinds of feed for different fishes, such as food fish, fish, shrimps, crab, eel, etc. The fish pellet machine applies to the pretreatment of the animal fodder so as to reduce loss of nutrition, advance the protein content.

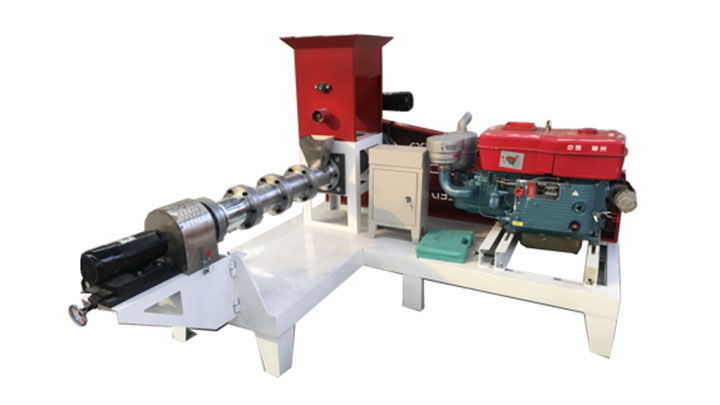

Diesel engine fish feed extruder is driven by a diesel engine and operates on this basis.Our factory provides a variety of die plates with 0.9-15mm aperture, which can extrude more than 30 kinds of common feed pellets. The capacity is from 30 kg/h to two tons per hour.

.jpg)

200-1000kg/h Small-scale Poultry and Livestock Feed Production Line 1-18ton/h Ring Die Poultry Feed Pellet Making Machine 60-1000 kg/h Flat Die Poultry and Livestock Feed Pellet Making Machine 300-2000kg/h Floating Fish feed pellet automatic production line 40-300kg/h Farm use Simple fish feed production line 180-4000kg/h Wet Way Floating Fish

2、Apr 27, 2016 — Fish Food Extrusion machine can produce different shapes food for cattle, sheep, dog, fish or cat etc. Through the pretreatment of the fodder, 3、Wet type fish food pellet extruder machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, ...

Search for used diesel engine fish feed extruder machines. Find Hanson and Caterpillar for sale on Machinio.

.jpg)

MS 3000 Extruder. The MS3000, Medium Shear Extruder, is designed for processing shaped products such as pet food and fish feed. The extruder combined with proper preconditioning allows for flow conditions within the barrel that enhances the final product shape. FEATURES: Ideal for small- to medium-volume applications; Easy start up and installation

90-400KG/H smallfish pellet machine 200-400KG/H small animal feed pellet machine 300-500KG/H small animal feed pellet machine 400-600KG/H such as Nigeria, Ghana, Philippines, Malaysia, Indonesia, Pakistan, Bangladesh, Sri Lanka etc. Fish Feed Production 0.5-4T/H Fish Feed Production Line for Sinking and Floating Feed.

.jpg)

4. After puffed feed pellet through high temperature will killing such as Escherichia coli and Salmonella, not only keep fish eat health food, also keep fish easy to eat and digest, make your fish growing fast. 5. Can make different size from 1mm-12mm , can feed from baby fish to big fish. 6. Can using motor and diesel according to your

.jpg)

Applicable industries: Manufacturing Plant, Food & Beverage Factory, Farms, Place of origin: Shandong, China, Voltage: Customer's diesel powered fish feed extruder dry diesel float fish feeding pellet machine in Shandong, China

Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong, China.

.jpg)

Fish Pellet Feed Making Machine Floating Fish Feed Machine Product Description Fish feed machine is suitable to make dry and wet type fish food pellet (catfish, aquarium, Tilapia, Freshwater fish and tropical fish etc.) 1. All fish food equipments are made of stainless steel. 2. The fish food whole line fully continuous and automatic. 3.

The produced fish feed pellets can float on the water surface and do not dissolve for more than 12 hours. According to the processing technology, fish feed extruders can be divided into dry type extruders and wet type extruders. According to the power supply, it can be divided into diesel engine feed extruder and Read More »

.jpg)

1) The output of the floating fish food extruder is low. 2) The tempering temperature is not high enough. 3) The main engine speed is low. 4) The electric heating temperature of the puffing chamber is low. 5) Conditioning moisture is too low. 6) Whether the material formula is changed.