.jpg)

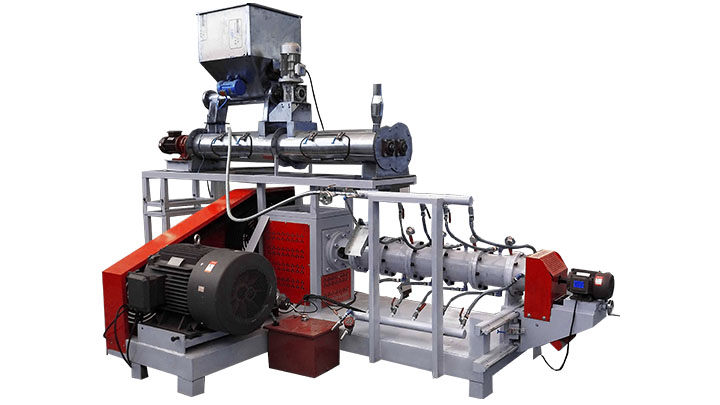

Twin Screw Extruder Machine | Fish feed, Feeding, Fish May 24, 2018 - Large capacity twin-screw fish feed plant is a new type of high output production line using double screw extruder. Double screw fish feed extruder is the core equipment in this production line that can process various shapes of floating fish feed.

Commercial fish feed cost : Market research shows that ordinary feed is $742 a ton; the extruded feed is $2938 a ton, among which floating feeds cost an average of 20 percent more than sinking feeds. For small-scale fish farmers in developing nations, rising feed and related costs are often too high to be absorbed into already-thin profit margins.

We provide floating fish feed extruder to Nigeria at the prices from US$2000 to US$7500, depending on what production capacity the customers choose. By the way, as the fish feed machine expert, we can customize the production capacities according to customers’ requirements. More specifically, the fish feed production line has capacities with

Price of Fish Feed Pellet Production Machine in Nigeria. For example, we provides wet type fish feed extruder to Nigeria at the prices from US$4 900 to US$34 000, depending on what production capacity the customers choose. Similarly, the prices of dry type fish feed extruder for Nigeria are lower, which can be provided from US$2 700 to US$29

Qualified Fish Feed Extruders and Feed Production Line by Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditio Tel:+86 19337889051

.jpg)

Floating fish feed pellet making extruder machine prices fish feed extruder manufacturing machine. Manufacturer: Sunward Product Display Product Description Specification Packing & Delivery To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided

The flat mold granulator is the first choice for breeding farms and professional households to reduce the cost of breeding and improve economic efficiency. The production capacity is 100-1200 kg per hour, and the small set consists of a pulverizer, a mixer, a screw conveyor, a regulator, a flat die granulator, a rotary screen and a cooler.

We can offer farmers top fish feed extruders to produce high quality fish feeds, and often update the fish farming knowledge for farmers. Moreover, the Ghana government has banned the import of frozen Tilapia to stimulate local fish farming and embarked on a highly ambitious National Aquaculture Development Plan (GNADP) with a production target

.jpg)

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

Reasonably Priced Fish Feed Pellet Machine in Nigeria. We provides wet type fish feed extruder at the prices from $4,900 to US$34,000, depending on what production capacity the customers choose. Similarly, the prices of dry type extruder are lower, from $2,700 to $29,000 depending on different production capacities.

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. Are added with a certain proportion of water to mix thoroughly. 2.

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

Multifunction floating fish feed pellet extruder Kenya- Lima Fish Feed MachineBest Solutions to Problems in Fish - Fish Feed Extruder Mini Floating Fish Feed Machine-30 kg/h. The Tel : + 8618236939453

.jpg)

Jul 21, 2020 · Fish Feed Pelletizing Process. The pelleting process includes the following steps: ♦ The mixed feed materials are fed into the fish feed extruder; ♦ The screw presses the material; ♦ Turning screw in the barrel causes a thermal energy (temperature is 110-130 °C); ♦ Finally, we have cooked and well treated fish feed pellets.