.jpg)

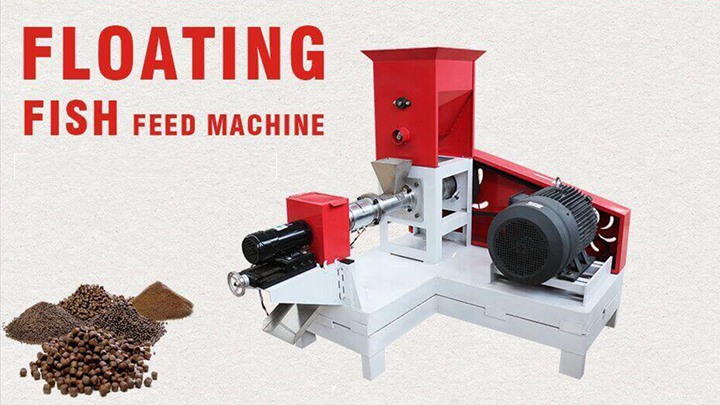

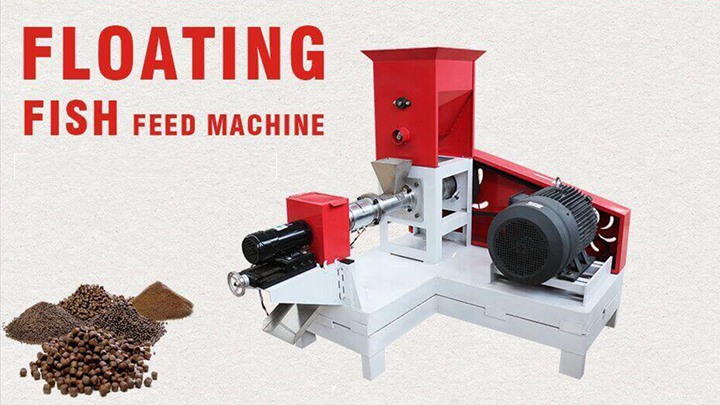

700-800KG/H fish feed extruder. Fish feed extrusion machine are the machinery used to produce extruded petfood, (floating) extruded aquatic feeds and extruded animal feeds. The extrusion cooking process, because it causes a high level of gelatinisation of starches, results in feeds with good water stability. this fish feed extruer machine can

.jpg)

With advanced single screw extruder by belt drive, floating fish feed machine is the ideal device in small and medium size feed processing plants and aqua farms. Our fish feed pellet machine can be divided into two types: dry type fish feed machine and wet type feed machine. The wet type is with the conditioner and need to equip the steam boiler.

.jpg)

Various capacities (60kg/h to 2t/h) are available to meet your specific demands, producing kinds of quality feed pellets for aquatic and pet feed. Super automation control, high production efficiency, our fish feed production line is the best choice.

Dec 21, 2020 · This 1t/h floating fish feed and 1-2t/h cattle chicken feed combined line project started in January 2019, the installation cycle is 60 days, covers an area of 15 * 9.5 * 8 meters,and the project is currently in production.The main equipment of the project includes: 37KW animal feed hammer mill grinding machine, 500kg/batch feed mixing machine

Capacity : 5T/H. Total Power : 298KW. Details. 100-150KG/H Floating Fish Feed Production Line In Nigeria. The 300-400kg/h Floating fish feed line In Cote d’Ivorie. 100KG/H Fish Feed Production Line In UK. 1-2TPH Capacity Complete High-end Aquatic Shrimp Feed Produc The 1-1.5T/H Fish Feed Line + 2TPH Chicken Feed Pellet Line ...

1: Sinking fish feed processing making extruder machine floating For Sale Singapore: 2: Sinking fish feed processing making extruder machine floating Process In Zimbabwe: 3: 120-150kg/h dry type floating fish pellet feed extrusion machine fish feed machine floating fish food feed Process In United Arab Emirates: 4

.jpg)

Our machine is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, etc. Floating fish feed machine also can make pet feed for the dog, cat, etc with different shape and chicken feed. The puffing fish feed pellets can float on the water surface without dissolution for over 12 hours. According

.jpg)

Advantages of our fish feed processing plant 1.This kind of fish feed extruder machine owns simple structure, wide application, and low noise. 2.It can improve the quality and floating time of the fish feed pellets. 3.

.jpg)

Best price 400kg/h fish food equipment,US $ 3000 - 30000 / Set, New, 2 YRS Henan Nongda Machinery Co., Ltd. gold supplier 2t/h fish feed granulator. LEARN MORE Floating Fish Feed Extruder

1-1.2 T/H Wet Type Fish Feed Production Line Wet type fish feed production plant is the best choice for medium and big sized feed mills and breeding farms. It adopts wet extrusion technology with high production capacity, mainly used in commercial scale fish farms. Twin-Screw Fish Feed Extruder

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

Automatic Animal Fish Feed Food Extruder Processing Making Machine - Buy Fish Feed Processing Machine,Fish Food Making Machine,Fish Feed Extruder Machine Product on

.jpg)

Jan 02, 2022 · Processing » Extruders » product ideas 2022 1-2t/h pet food machine germany fish feed extruder on sale selling dog food machine in Jinan, China ‹ ›

Fish feed making machine is also named fish feed extruder, and it is used for processing for dogs and cats (pet food), birds, piglets, frogs, sinking and floating aquatic feeds for fish. Which is high and new technical program as to catch the developing pet food market.

feed pellet making line is all-purpose for chicken,duck,cattle,cow,goat,sheep and fish feed production with 3-5 tons per hour capacity. This feed pellet production line has manual and automatic dosing system for your choice requiring that the raw mateial should be 100% grain for poultry or 70% grain and 30% fodder mixed together for livestock.