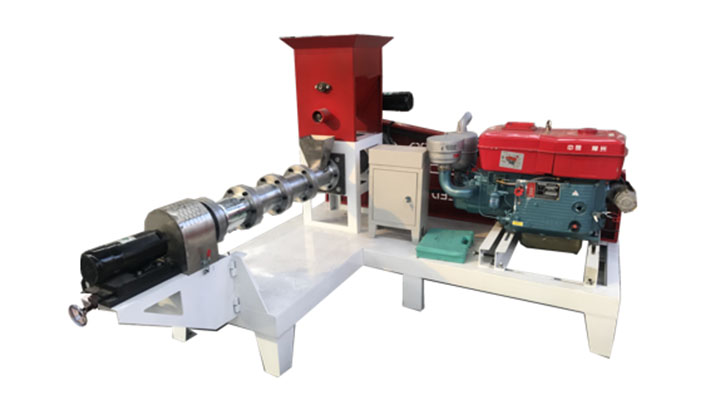

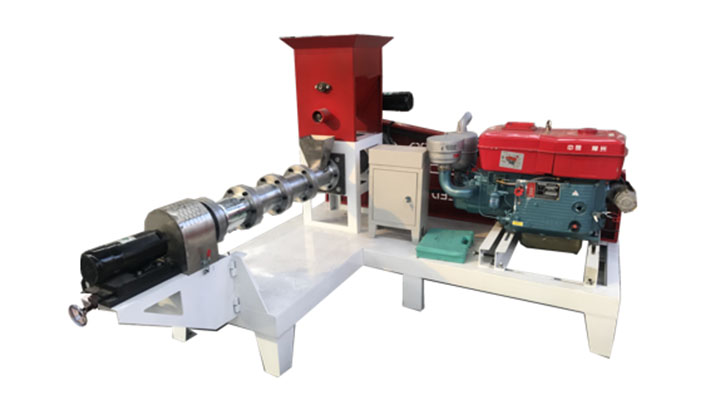

1.Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate. 2. The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder. 3.

.jpg)

Catfish feed production method: Weigh all feed stuffs – fully grinding all raw materials via fish feed grinder machine – pass through 50 mesh for screening – mixing – extrusion. Notice: 1. All feed stuffs should be cleaned before grinding, if not, impurities of feed stuffs would lower catfish feed quality and even damage the fish feed

Fish Food Processing Machine Manufacture Website : www.lyalls.net Telephone : +1-780-435-8600 Address : 3376-86th Street, Edmonton, Alberta T6E 5N9, Canada

.jpg)

Single-screw design has two types of fish feed extruders: dry type fish feed extruder and wet type fish feed extruder. The big difference between the “dry” and the “wet” extruder is: a dry extruder does not require an external source of heat or steam for injection or jacket heating that required by wet feed extruder.

Mar 26, 2022 · Reasonable price will be given according to your needs. We mainly produce fish feed extrusion machine, artificial rice machine, puffed snacks machine, pet food machine, etc. If interested, please feel free to contact me. My whatsapp: +86 176 8668 2883 / +86 186 6376 4200. My email: lead@sunpring.com.

.jpg)

We ensure that fish farmers around East Africa can practise responsible and effective aquaculture. Together, we are making a sustainable contribution to food production for a rapidly growing global world population. Our aim is to provide feed for healthy fish that is nutritious and of an exceptional quality for today's demanding consumer.

.jpg)

Tilapia Feed Formulation and Feeding Technique. Posted at 08:49h in Application. 38 Likes. Share. Different fish feed formulations can be made to satisfy Tilapia demands in different growth periods. Fish feeding should keep the rules: fixed time, fixed place, fixed quality and fixed quantity, and also consider four factors: season, weather

Jun 28, 2022 · Fish Feed Extrusion Process with Extruder MachineEquipment – Fish Feed Extruder. Currently, the main extrusion equipment applied in aquatic feed production is single screw fish fe Tel: +8619337889051

What is Aquatic Feed Production System "Fish Feeding Machine for Aquarium", Fish Feed manufacturers & suppliers on Video Channel of LimaFeedPelletizer.com.

.jpg)

Nov 09, 2018 · Fish feed extrusion process means the procedure of how to turn the mixture of feed ingredients into extruded fish feed with extrusion machine - fish feed extruder

Drifting fish feed produced by this plant has a beautiful look, unique preference, and fish feed-nutrient, appropriate for different fish and fishs. The fish feed pellet line is widely used in animal feed production, such as fishs, felines, fish, foxes, birds, and other animals. Fish Feed . Best Solutions to Problems in Fish - Fish Feed Extruder

Single-screw design has two types of fish feed extruders: dry type fish feed extruder and wet type fish feed extruder. The big difference between the “dry” and the “wet” extruder is: a dry extruder does not require an external source of heat or steam for injection or jacket heating that required by wet feed extruder.

Fish Feed Extrusion Process | Extruded Aqua Feed with 2000kg/h shrimp feed machine Feed size 7 mm kenya. ... Tel:+8617337771729 . E-mail:sale@limamachinery.com ...

.jpg)

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

fish feed extrusion process. Pelleting is to process the mixture of feed ingredients under high temperature, moisture and high pressure within floating fish feed pellet mill – raw materials are pressed through die mold. According to lots of experience, too little or too much steam and heat added to the ingredients would produce pellet with