Buy Online and call or use the app when you arrive. We'll bring it to your car or truck. While shopping online, select "Contactless Curbside Pickup In Store" for eligible items. Select the store where you would like to pick up your items. Place your order and wait to receive a "Ready For Customer Pickup" e-mail.

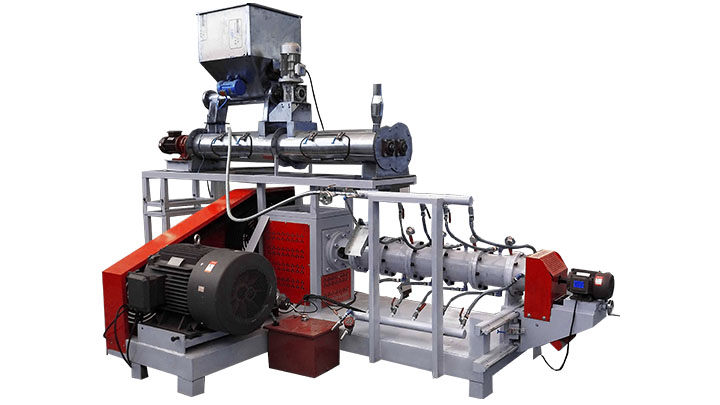

15-132 KW. According to the characteristics of aquatic feed and many years of experience, we design a fish feed extruder with double-layer conditioner, which is more suitable for the production of aquatic feed, fish feed and shrimp feed. New multi-channel functional modifier with long retention time. It consists of a preconditioner for centralized mixing of materials and steam, a holder for long-term heat preservation to promote gelatinization, a crusher for unifying feed structure in the

.jpg)

3. Fish Docks. During the summer, fish the docks. Crappie will utilize shallow-water docks in as shallow of water as 3 feet and deeper marina docks that could dropoff to 25 feet. These are great places to find crappie as they provide cool water, shade, and plenty of food. 4.

Oct 11, 2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

Crappie fish requires stocking them in a well-spaced environment, so you should always go for a larger tank. The recommended stocking density for 2 to 3 crappie fish is 80 gallons. Thus, your fish tank should be able to fill at least 80 gallons of water. However, if you wish to raise 4 or more crappie fish, you should go for larger tanks.

.jpg)

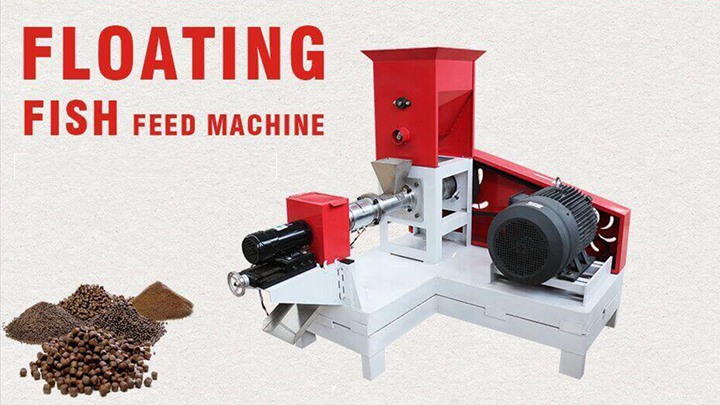

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

When fishing brush piles or standing timber in deeper water, use a slip bobber and set it at the depth you find crappie suspended in the cover. Use a couple of large bb split shots or some 1/8- or 1/4-ounce pinch-on sinkers to drop your minnow to the desired depth. A longer rod ranging from 7 feet for casting or 10 to 12 feet for flipping to

Equipment – Fish Feed Extruder. Currently, the main extrusion equipment applied in aquatic feed production is single screw fish feed extruder which is also divided into dry type fish feed extruder and wet type fish feed extruder machine. With different parameters and feed formulation, fish farmers and feed plants can make floating, sinking and slow-sinking feed with high quality and nutrition so as to adapt for diverse ingestion requirements of various aquatic animals.

.jpg)

3 parts mechanism. Feeding section: This section has a larger pitch and is mainly used for conveying and compressing materials, so that the spiral groove is filled with feed.

.jpg)

As they mature and reach adulthood, they still consume insects and aquatic shrimp, tadpoles, and crayfish but their diet evolves to feeding mostly on baitfish. Crappie readily consume small bluegills, small yellow perch, small bass, along with shiners, suckers, small shad, and minnows. The best bait for crappie are fathead minnows.

.jpg)

200kgh fish feed extruder machinefloating fish feed extruder machine. Manufacturer: Ainuok; fish feed extruder machinefloating fish feed extruder machine Machine Product Description 1.Floating rainbow trout shrimp guppy cat fish fish feed pallet machine uses corn, soybeans (bean cakes), animal scraps, et

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

Apr 21, 2022 · Tip: using fish feed extruder produce (sinking and floating) feed pellets by own, all of above requirements can be met. III.Feeding Method of Freshwater Fish The goal of feeding in pond is to feed the fishes with required quality, quantity, and feeding time per day. So as to achieve the best production effect and benefit.

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

.jpg)

Nutritious Food for Commercial Fish Farms. Star Milling offers custom formulations with low minimum order requirements in either bulk, super sack, or sack. We offer pellet sizes for all stages of growth from fry through production stage. Star Milling has the products and resources you need to maintain a healthy and balanced diet for your fish.