As they mature and reach adulthood, they still consume insects and aquatic shrimp, tadpoles, and crayfish but their diet evolves to feeding mostly on baitfish. Crappie readily consume small bluegills, small yellow perch, small bass, along with shiners, suckers, small shad, and minnows. The best bait for crappie are fathead minnows.

.jpg)

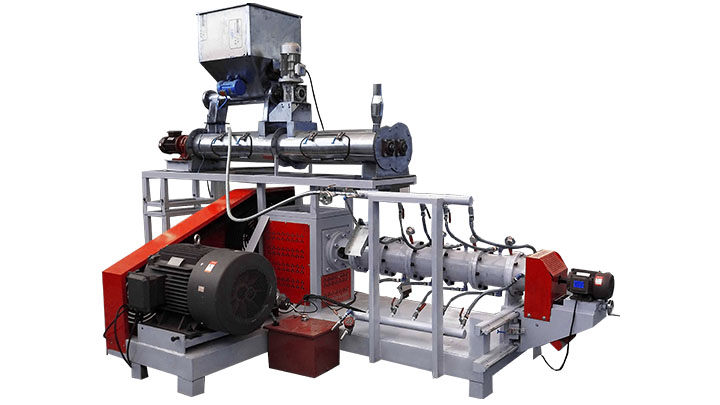

Capacity: 0.1-5 T/H. Main Power: 15-132 KW. According to the characteristics of aquatic feed and many years of experience, we design a fish feed extruder with double-layer conditioner, which is more suitable for the production of aquatic feed, fish feed and shrimp feed. New multi-channel functional modifier with long retention time.

A short summary of this paper. 33 Full PDFs related to this paper. Read Paper. International Journal of Scientific & Engineering Research, Volume 7, Issue 8, August-2016 1378 ISSN 2229-5518 DESIGN AND CONSTRUCTION OF A FISH FEED EXTRUDER 1 I.F. Odesola, *2R.A. Kazeem , 3N.C. Ehumadu Abstract- In fish farming, the consumption of feeds in pellet

fish feed extruder factory manufacturers/supplier, China fish feed extruder factory manufacturer & factory list, find best price in Chinese fish feed extruder factory manufacturers, suppliers, factories, exporters & wholesalers quickly on LimaFeedPelletizer.com.

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

.jpg)

Feb 26, 2009 · We used an ultra-lightweight 14-foot, three-piece BnM crappie jig pole with their factory engineered spinning reel designed just for crappie fishing. These poles can really reach out into the structure, and are perfect for setting out multiple poles.”. Another angler, Steve Coleman, explained what worked for him.

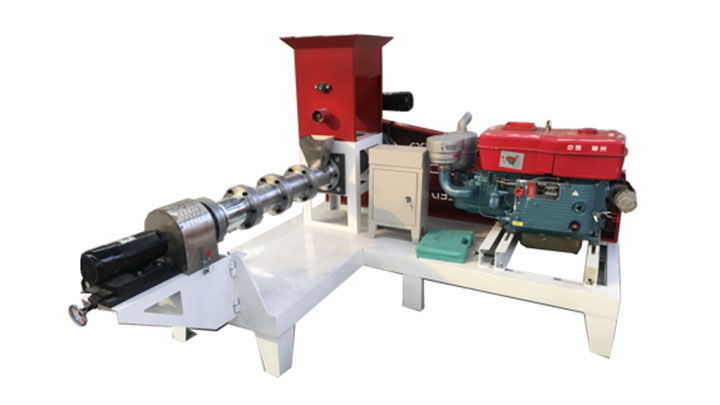

Extruder for Animal Feed - Fish, Cats and Dogs. Extruder for Animal Feed - Fish, Cats and Dogs Main engine: 15kw | Cutting knife motor: 400w | Power motor: 400w | Production: 100-200kg/h | Machine dimensions: 1300x1200x1200mm | Machine weight: 500kgs

.jpg)

Animal Floating Fish Feed Extruder Processing Machine 150-5000 kg/h Capacity SLG135 Fish Feed Extruder , Twin Screw Fish Food Making Machine ABB Inverter Sinking Fish Feed Extruder Machinery Plant , Fish Feed Production Machine

Fish Feed Extruders with Various Production Capacities. Our Fish Feed Extruders are with improved qualities and affordable cost. It includes: dry type single screw extruder, wet type single screw extruder, double screw extruder, ring die fish feed pellet mill, and diesel engine extruder machine. We can satisfy different production requirements.

.jpg)

The machine can produce floating feed pellets of all kinds of aquatic animal. mainly sinking pellets,because the density of the pellets are big, if you want to make floating feed,so you need to buy one more extruder. A. The fish feed pellet line is widely used in production of animal feed, such as dogs, cats, fish, foxes, birds and other pets.

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. Are added with a certain proportion of water to mix thoroughly. 2.

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

Oct 11, 2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

.jpg)

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet