.jpg)

high capacity floating fish feed mill plant thailandFish feed extruder is for manufacturing aquatic feed for Thailand freshwater aquaculture. However the availability and high co Tel:+8619337889051

The Difference between Dry-way and Wet-way Fish Feed Exturder 1:Different production processes According to whether the material is steam quenched and tempered before entering the extruder barrel (expansion cavity), it is divided into dry expansion and wet expansion.

.jpg)

Crappie is absolutely good for eating. Both species are completely harmless to eat and a big part of the seafood diet of people all over North America. Particularly in the U.S. south. People have been eating and enjoying crappie for hundreds of years, developing cooking methods that bring out all the best flavors in this gorgeous fish.

.jpg)

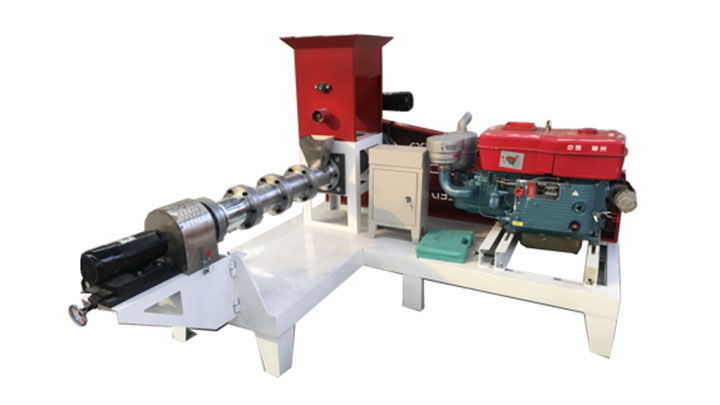

Our Fish Feed Extruders are with improved qualities and af Contact US. E-MAIL: ... TEL: 8617337771729 Crappie fish feed pellet machine diesel-type in Saudi Arabia ...

.jpg)

Fish Feed Extruder Machine Price –Lima Fish Feed We have two types of fish feed extruder, dry type and wet type model fish feed machine. Our machines can produce both floating Tel:+8619337889051

Animal Feed Pelleting - CPM: Process Equipment and The process of producing feed pellets can roughly be described as a plastic molding operation of the extrusion type. Feed ingred+86 19337889051

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

Jan 27, 2018 · Crappie are like other predator fish. They will suspend and eat bait grouped in balls and the crappie school to feed on them. The crappie have eyes that naturally look forward and up while standing still. They hang below or to the sides of these bait balls. Never above as they don't look down without putting the tails in an up postion which is

.jpg)

Feed Pellet Mill Manufacturer. Expert In Animal Feed Application: Fish oil,Fishmeal,Soya protein,Wheat gluten,Wheat and peas, etc. pellet dia: 0.9-10mm. customized

.jpg)

Aug 20, 2021 · Crappie Appearance. The crappie fish is characterized by an oval-shaped body, silvery-green scales, a downturned mouth, and spiny fins and gill covers. The two species in this genus are fairly simple to distinguish from each other. The black crappie fish can be identified by the irregular black spots arranged around the body.

.jpg)

Fish Feed Extruder Machine Pfish feed – Lima Fish Feed 2021 - 05 - 08 Best Fish feed machines manufacturer- Lima Fish Feed Machinery Dry type fish feed extruder, also called floating fish feed machine, is wLIMAely used for produce high-grade aquatic feed pellets for fish, fishfish, shrimp, crab, lobsters, etc.

.jpg)

Jun 28, 2022 · Mar 28, 2014 · Thornhill says they can be successfully raised in farm ponds that meet certain criteria. "Crappie are sight feeders, so you want clear water, visibility of 2-1/2 to 3-feet or so," says Thornhill.

The United States currently has 2660 aquatic products wholesale markets with 12,800 employees, 1913 aquatic products processing factories with 77,200 employees, 549 aquatic canning enterprises. So the fish feed industry of the United States is also not resigned to playing second fiddle. The main cultured fish species in the United States

Dec 15, 2020 · Fish feed e xtruder and expander are machines that mainly apply extrusion and expansion technology in feed pellet production. An extruder is a bio-reactor providing the necessary pressure to force feed mash in the barrel through a restrictive die. Through changes in temperature, pressure, and shear within the barrel, the raw material is