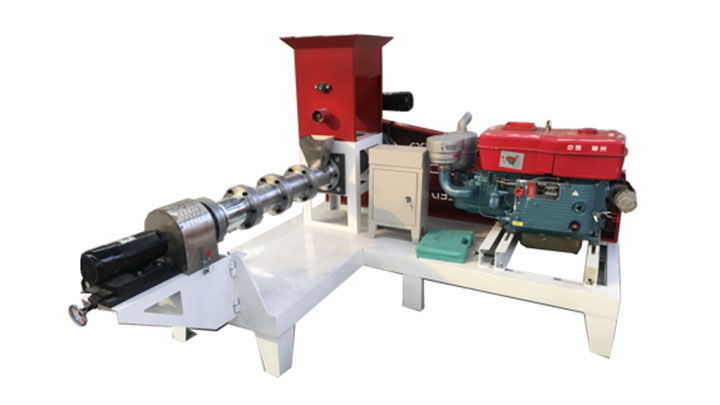

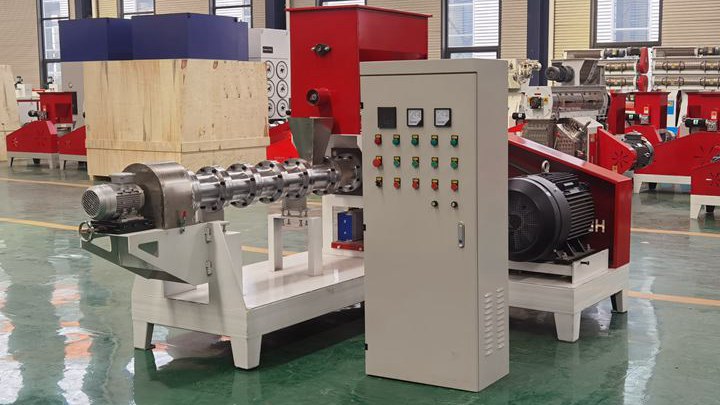

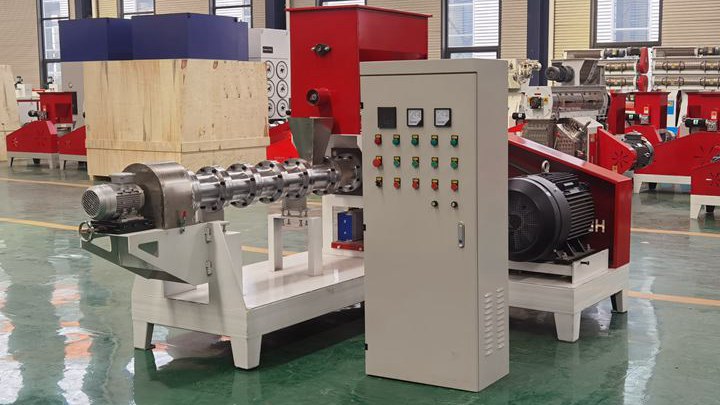

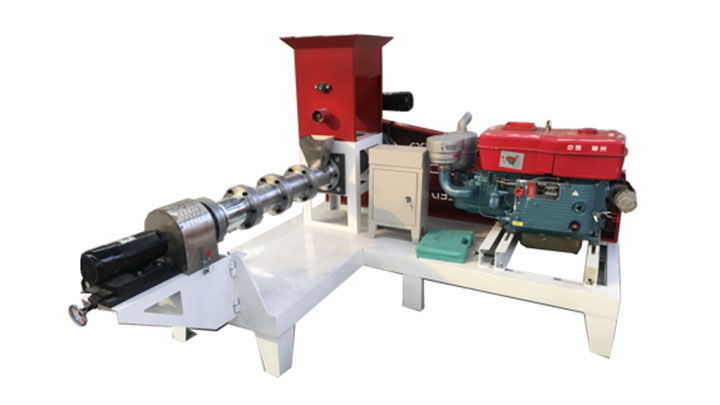

Dry Type Fish Feed Extruder Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

Catfish Fish Meal Floating Feed Extruder Machine_OKCHEMCatfish Fish Meal Floating Feed Extruder Machine_OKCHEM Please note that all emails sent by OKCHEM are from ***@okchem.com, Tel:+8619337889051lima37@limamachinery.com

Apr 03, 2016 · One turnkey project for sinking fish feed plant in Saudi Arabia. Our client is one of the big in-land aquaculture operations in the world. We are proud to contribute to the progress of the aquaculture industry in Saudi Arabia. Our client purchased a turnkey extrusion line for producing 5 TPH sinking feed. All the steel structures, machinery, and control system are provided from Taiwan.

6.The raw materials can be used in producing pellet feed is various. Running-in of Floating Fish Feed Extruder. 1.Blend 5 or 10 kilogram mash feed with edible oil of 5% or 10% together. If the mash feed becomes caking, we should disperse them to keep the feed in powder condition. 2.Put the feed into the extruder before we turn on the machine.

.jpg)

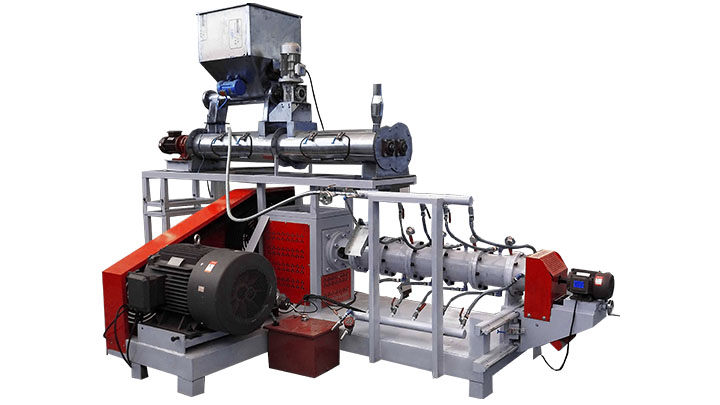

Model :LM80 Capacity (kg/h):200-300kg/h Main power (kw):22kw Feeder power (kw):0.6kw Screw Diameter (mm):Φ80 Cutter power (kw):0.6kw Machine size (mm):4000*2100*1900mm

As they mature and reach adulthood, they still consume insects and aquatic shrimp, tadpoles, and crayfish but their diet evolves to feeding mostly on baitfish. Crappie readily consume small bluegills, small yellow perch, small bass, along with shiners, suckers, small shad, and minnows. The best bait for crappie are fathead minnows.

Buy ARASCO Fish and Shrimp feed and you can count on: o Feeds that are scientifically developed for the specific requirements and challenges of each different species and our regional environments. o Feeds that meet the needs of each growth stage in the lifecycles of your freshwater or marine species. We produce our feeds in 2mm, 4mm and 6mm

Fish Feed Machines and Floating Feed Production Line ManufacturerFish Feed Extruders with Various Production Capacities. Our Fish Feed Extruders are with improved qualities and af E-MAIL:lima37@limamachinery.com

9000 Series Extruder. Insta-Pro Model 9000 high-shear dry extruder maximizes oil-seed product value. Ideal for organic, specialty and identity-preserved oilseeds. The Insta-Pro model 9000 extruder is an innovative, chemical-free processing solution providing a nutrient-dense product with exceptional ROI for producers of meat, milk and eggs

.jpg)

Oct 11, 2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

.jpg)

high capacity floating fish feed mill plant thailandFish feed extruder is for manufacturing aquatic feed for Thailand freshwater aquaculture. However the availability and high co Tel:+8619337889051

Jun 28, 2022 · "Crappie are sight feeders, so you want clear water, visibility of 2-1/2 to 3-feet or so," says Thornhill. "You also want to have established, rooted vegetation in the pond, at least up to 20% of the surface area because crappie need a place to hide.

Apr 14, 2022 · The best crappie bait for ponds is a steady supply of natural forage and baitfish for the crappie to eat. This is usually juvenile bluegill (less than 3 inches), mosquitofish, shiners, shad, or fathead minnows. Plus all the other good stuff that grows in a nutrient-rich and healthy pond like crustaceans, insects, larvae, eggs, etc.

.jpg)

Feed Extruder Machine Full Auto Feed Extruder Machine Line And Processing Equipment SLG95 / SLG120 Fish Prawn Feed Machine Twin Screw Extruder Self Cleaning CE Approved Tilapia Fish Feed Production Machine , Floating Fish Feed Processing Line Fish Feed Extruder Continuous Floating Fish Feed Pellet Machine , Fish Feed Equipment

1.Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate. 2. The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder.