LM40 30-40kg/h Fish Feed Machine by Electric/Diesel Engine Combining advanced Europe technology with years of practical experience, we have successfully developed 12 series of fis+8619337889051 Email:lima37@limamachinery.com

The 1-1.2T/H Bird and camel Feed Pellet Line In Qatar. Country Qatar; Date Aug 8th,2017; Name Bird and camel Feed Pellet Line; Capacity 1-1.2T/H; Total Power 92KW; Workshop size about this project 6m*3m*7m (L*W*H) Main Machines in this complete line

.jpg)

Crappie fish feed pelletizers design in Canada Design and fabrication of a modified fish feed pelletizing Fish feed pelletizing machine was designed and fabricated with the aim to improve on existing local pelletizers; encoura+8619337889051 Email:lima37@limamachinery.com

.jpg)

Basic Info: Fish feed production line are the all-automatic and food grade processing line. You can make any shape of the pet food according to different market Model Number: 1-1.2t/H

The 100-150kg/h Floating fish feed line In Botswana Country : Botswana Capacity: 100-150kg/hour The 1-1.5T/H Fish Feed Line + 2TPH Chicken Feed Pellet Line In Uzbekistan Country : Uzbekistan Capacity: 1-1.5T/H 100KG/H Fish Feed Production Line In UK Country : UK

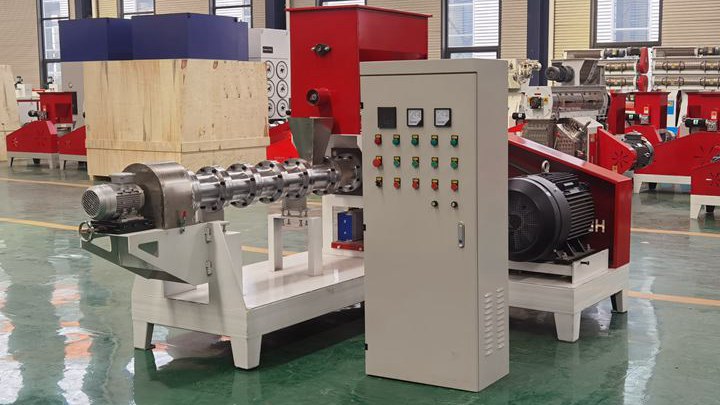

40-800kg/h Electric Engine Floating Fish Feed Pellet Machine Diesel Engine Floating Fish Feed Extruder Machine 180-4000kg/h Wet Way Floating Fish feed pellet machine 40-300kg/h small floating fish feed production line 300-2000KG/H Floating Fish feed pellet automatic production line 60-1000 kg/h Flat Die Poultry and Livestock Feed Pellet Making

.jpg)

100kg/h fish feed extruder machine parts Feed size 6 mm in 300-500 kg/h floating fish feed extruder machine dry extruding type 300-500 kg/h floating fish feed extruder machine d Tel : +8619337889051

Jun 28, 2022 · Crappie fish requires stocking them in a well-spaced environment, so you should always go for a larger tank. The recommended stocking density for 2 to 3 crappie fish is 80 gallons. Thus, your fish tank should be able to fill at least 80 gallons of water. However, if you wish to raise 4 or more crappie fish, you should go for larger tanks.

.jpg)

Aug 19, 2007 · A single crappie can lay 17000-20000 eggs at one time. Hog pelllets work great and kernel corn is also in exspensive. I would put some bass or other predator in to keep the population down. If it gets overstocked it will only produce small fish. A single crappie can lay 17000-20000 eggs at one time.

.jpg)

Electric control cabinet -Control each equipment of the production line. Counter-Flow Feed Pellet Cooler 3-5T/H,0.75KWCooler bring down the pellets at normal temperature (+4° max). Animal Feed Pellet Machine 1-2T/H,22KWGood pellet mill can ensure that produce good pellets. Vibrating Screen Classifier 3-6T/H,1.5KWScreen for impurities and grades.

.jpg)

The animal feed mill process is special, customers make bird feed and camels with extruder feed, which is based on the customer's special feed formula; Variety of pellet sizes, 2mm, 3mm, 4mm, 6mm, to meet the feeding of various production stages. Equipment delivery of customizable easy to use 1-1.2t/h animal feed plant for sale Qatar

.jpg)

Our Fish Feed Extruders are with improved qualities and af. Chicken Feed Pellet Line 1-2t ... Crappie fish feed pellet machine diesel-type in Saudi Arabia

1-1.2t/H Fish Feed Manufacturing Machinery Floating Fish Product Description 1-1.2T/H Fish Feed Manufacturing Machinery Floating Fish Pellet Production Line Introduction of Floati+8619337889051 Email:lima37@limamachinery.com

Apr 14, 2022 · The best crappie bait for ponds is a steady supply of natural forage and baitfish for the crappie to eat. This is usually juvenile bluegill (less than 3 inches), mosquitofish, shiners, shad, or fathead minnows. Plus all the other good stuff that grows in a nutrient-rich and healthy pond like crustaceans, insects, larvae, eggs, etc.

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet